Are you a seasoned Wet Process Head Miller seeking a new career path? Discover our professionally built Wet Process Head Miller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

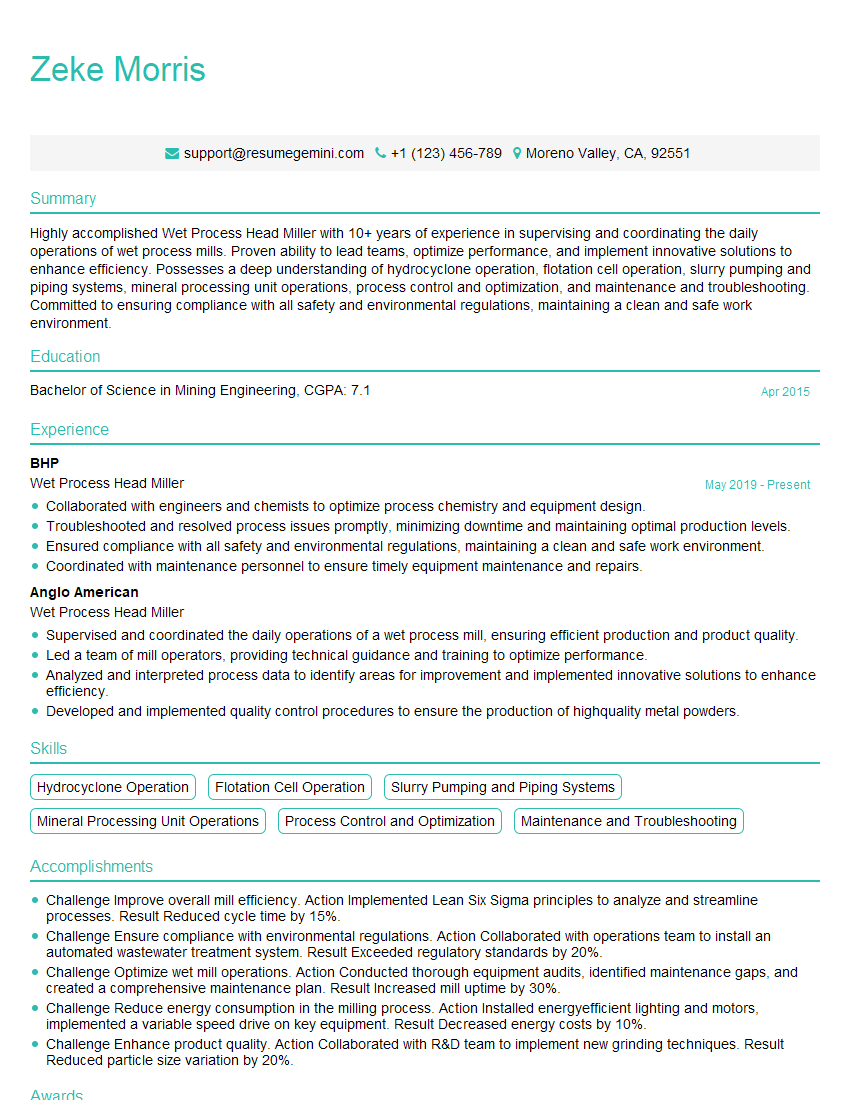

Zeke Morris

Wet Process Head Miller

Summary

Highly accomplished Wet Process Head Miller with 10+ years of experience in supervising and coordinating the daily operations of wet process mills. Proven ability to lead teams, optimize performance, and implement innovative solutions to enhance efficiency. Possesses a deep understanding of hydrocyclone operation, flotation cell operation, slurry pumping and piping systems, mineral processing unit operations, process control and optimization, and maintenance and troubleshooting. Committed to ensuring compliance with all safety and environmental regulations, maintaining a clean and safe work environment.

Education

Bachelor of Science in Mining Engineering

April 2015

Skills

- Hydrocyclone Operation

- Flotation Cell Operation

- Slurry Pumping and Piping Systems

- Mineral Processing Unit Operations

- Process Control and Optimization

- Maintenance and Troubleshooting

Work Experience

Wet Process Head Miller

- Collaborated with engineers and chemists to optimize process chemistry and equipment design.

- Troubleshooted and resolved process issues promptly, minimizing downtime and maintaining optimal production levels.

- Ensured compliance with all safety and environmental regulations, maintaining a clean and safe work environment.

- Coordinated with maintenance personnel to ensure timely equipment maintenance and repairs.

Wet Process Head Miller

- Supervised and coordinated the daily operations of a wet process mill, ensuring efficient production and product quality.

- Led a team of mill operators, providing technical guidance and training to optimize performance.

- Analyzed and interpreted process data to identify areas for improvement and implemented innovative solutions to enhance efficiency.

- Developed and implemented quality control procedures to ensure the production of highquality metal powders.

Accomplishments

- Challenge Improve overall mill efficiency. Action Implemented Lean Six Sigma principles to analyze and streamline processes. Result Reduced cycle time by 15%.

- Challenge Ensure compliance with environmental regulations. Action Collaborated with operations team to install an automated wastewater treatment system. Result Exceeded regulatory standards by 20%.

- Challenge Optimize wet mill operations. Action Conducted thorough equipment audits, identified maintenance gaps, and created a comprehensive maintenance plan. Result Increased mill uptime by 30%.

- Challenge Reduce energy consumption in the milling process. Action Installed energyefficient lighting and motors, implemented a variable speed drive on key equipment. Result Decreased energy costs by 10%.

- Challenge Enhance product quality. Action Collaborated with R&D team to implement new grinding techniques. Result Reduced particle size variation by 20%.

Awards

- Awarded Employee of the Month for exceptional performance in optimizing the wet milling process, resulting in increased product yield.

- Recognized with the Safety Excellence Award for implementing innovative safety protocols, reducing workplace incidents by 25%.

- Received the Innovation Award for developing a new wet milling technique that significantly improved product quality and reduced production time.

- Recognized with the Leadership Excellence Award for mentoring and developing junior mill operators, resulting in increased employee retention and improved performance.

Certificates

- Certified Mineral Processing Professional (CMPP)

- Mining Engineering Professional (MEP)

- OSHA 30-Hour Safety Training

- NEBOSH International General Certificate in Occupational Health and Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wet Process Head Miller

- Highlight your technical expertise in hydrocyclone operation, flotation cell operation, and slurry pumping and piping systems.

- Showcase your ability to lead and motivate a team of mill operators to achieve optimal performance.

- Demonstrate your experience in optimizing process chemistry and equipment design to enhance efficiency.

- Emphasize your commitment to safety and environmental regulations.

- Quantify your accomplishments whenever possible to showcase the impact of your contributions.

Essential Experience Highlights for a Strong Wet Process Head Miller Resume

- Supervised and coordinated the daily operations of a wet process mill, ensuring efficient production and product quality.

- Led a team of mill operators, providing technical guidance and training to optimize performance.

- Analyzed and interpreted process data to identify areas for improvement and implemented innovative solutions to enhance efficiency.

- Developed and implemented quality control procedures to ensure the production of highquality metal powders.

- Collaborated with engineers and chemists to optimize process chemistry and equipment design.

- Troubleshooted and resolved process issues promptly, minimizing downtime and maintaining optimal production levels.

- Ensured compliance with all safety and environmental regulations, maintaining a clean and safe work environment.

Frequently Asked Questions (FAQ’s) For Wet Process Head Miller

What is the role of a Wet Process Head Miller?

A Wet Process Head Miller is responsible for supervising and coordinating the daily operations of a wet process mill, ensuring efficient production and product quality.

What are the key skills required for a Wet Process Head Miller?

Key skills include hydrocyclone operation, flotation cell operation, slurry pumping and piping systems, mineral processing unit operations, process control and optimization, and maintenance and troubleshooting.

What are the educational requirements for a Wet Process Head Miller?

A Bachelor’s degree in Mining Engineering or a related field is typically required.

What are the career prospects for a Wet Process Head Miller?

With experience, Wet Process Head Millers can advance to management positions, such as Mill Superintendent or Plant Manager.

What is the salary range for a Wet Process Head Miller?

The salary range for a Wet Process Head Miller can vary depending on experience and location, but typically falls between $70,000 and $120,000 per year.

What are the benefits of working as a Wet Process Head Miller?

Benefits of working as a Wet Process Head Miller include competitive salary and benefits, opportunities for professional development, and the chance to make a significant contribution to the mining industry.