Are you a seasoned Wheel Buffer seeking a new career path? Discover our professionally built Wheel Buffer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

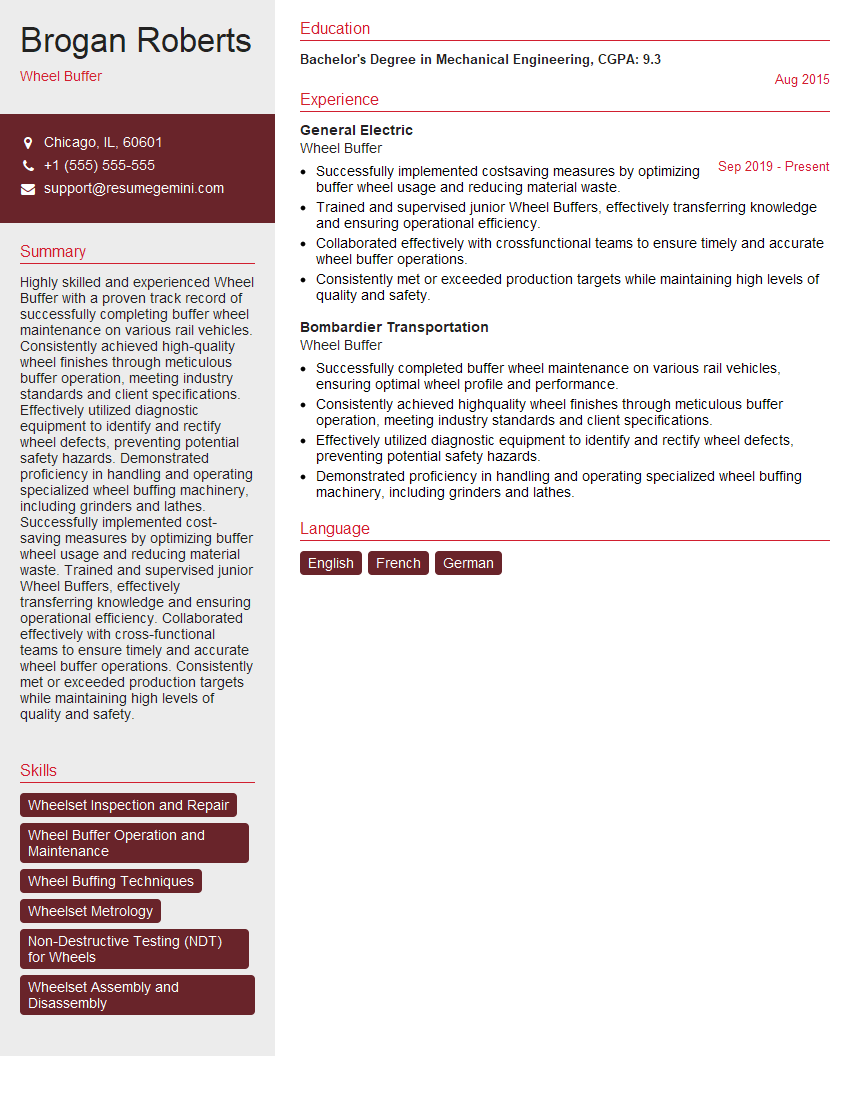

Brogan Roberts

Wheel Buffer

Summary

Highly skilled and experienced Wheel Buffer with a proven track record of successfully completing buffer wheel maintenance on various rail vehicles. Consistently achieved high-quality wheel finishes through meticulous buffer operation, meeting industry standards and client specifications. Effectively utilized diagnostic equipment to identify and rectify wheel defects, preventing potential safety hazards. Demonstrated proficiency in handling and operating specialized wheel buffing machinery, including grinders and lathes. Successfully implemented cost-saving measures by optimizing buffer wheel usage and reducing material waste. Trained and supervised junior Wheel Buffers, effectively transferring knowledge and ensuring operational efficiency. Collaborated effectively with cross-functional teams to ensure timely and accurate wheel buffer operations. Consistently met or exceeded production targets while maintaining high levels of quality and safety.

Education

Bachelor’s Degree in Mechanical Engineering

August 2015

Skills

- Wheelset Inspection and Repair

- Wheel Buffer Operation and Maintenance

- Wheel Buffing Techniques

- Wheelset Metrology

- Non-Destructive Testing (NDT) for Wheels

- Wheelset Assembly and Disassembly

Work Experience

Wheel Buffer

- Successfully implemented costsaving measures by optimizing buffer wheel usage and reducing material waste.

- Trained and supervised junior Wheel Buffers, effectively transferring knowledge and ensuring operational efficiency.

- Collaborated effectively with crossfunctional teams to ensure timely and accurate wheel buffer operations.

- Consistently met or exceeded production targets while maintaining high levels of quality and safety.

Wheel Buffer

- Successfully completed buffer wheel maintenance on various rail vehicles, ensuring optimal wheel profile and performance.

- Consistently achieved highquality wheel finishes through meticulous buffer operation, meeting industry standards and client specifications.

- Effectively utilized diagnostic equipment to identify and rectify wheel defects, preventing potential safety hazards.

- Demonstrated proficiency in handling and operating specialized wheel buffing machinery, including grinders and lathes.

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wheel Buffer

- Highlight your experience and skills in buffer wheel maintenance and repair

- Demonstrate your knowledge of wheel buffing techniques and wheelset metrology

- Showcase your ability to identify and rectify wheel defects using NDT techniques

- Emphasize your experience in training and supervising junior Wheel Buffers

Essential Experience Highlights for a Strong Wheel Buffer Resume

- Performing buffer wheel maintenance on various rail vehicles, ensuring optimal wheel profile and performance

- Consistently achieving high-quality wheel finishes through meticulous buffer operation, meeting industry standards and client specifications

- Effectively utilizing diagnostic equipment to identify and rectify wheel defects, preventing potential safety hazards

- Demonstrating proficiency in handling and operating specialized wheel buffing machinery, including grinders and lathes

- Successfully implementing cost-saving measures by optimizing buffer wheel usage and reducing material waste

- Training and supervising junior Wheel Buffers, effectively transferring knowledge and ensuring operational efficiency

- Collaborating effectively with cross-functional teams to ensure timely and accurate wheel buffer operations,Consistently meeting or exceeding production targets while maintaining high levels of quality and safety

Frequently Asked Questions (FAQ’s) For Wheel Buffer

What are the primary responsibilities of a Wheel Buffer?

The primary responsibilities of a Wheel Buffer include performing buffer wheel maintenance on various rail vehicles, ensuring optimal wheel profile and performance, consistently achieving high-quality wheel finishes through meticulous buffer operation, meeting industry standards and client specifications, effectively utilizing diagnostic equipment to identify and rectify wheel defects, preventing potential safety hazards, demonstrating proficiency in handling and operating specialized wheel buffing machinery, including grinders and lathes, successfully implementing cost-saving measures by optimizing buffer wheel usage and reducing material waste, training and supervising junior Wheel Buffers, effectively transferring knowledge and ensuring operational efficiency, collaborating effectively with cross-functional teams to ensure timely and accurate wheel buffer operations, consistently meeting or exceeding production targets while maintaining high levels of quality and safety.

What are the key skills required to be a successful Wheel Buffer?

The key skills required to be a successful Wheel Buffer include wheelset inspection and repair, wheel buffer operation and maintenance, wheel buffing techniques, wheelset metrology, non-destructive testing (NDT) for wheels, wheelset assembly and disassembly.

What are the educational requirements to become a Wheel Buffer?

The educational requirements to become a Wheel Buffer typically include a Bachelor’s Degree in Mechanical Engineering or a related field.

What are the career prospects for a Wheel Buffer?

The career prospects for a Wheel Buffer are generally positive, with a growing demand for skilled professionals in the rail industry. Wheel Buffers can advance to supervisory roles or specialized positions within the field.

What are the challenges faced by a Wheel Buffer?

The challenges faced by a Wheel Buffer can include working in physically demanding conditions, exposure to noise and vibration, and the need to stay up-to-date with industry standards and regulations.

What are the safety precautions that a Wheel Buffer must follow?

The safety precautions that a Wheel Buffer must follow include wearing appropriate personal protective equipment (PPE), following established safety protocols, and being aware of potential hazards in the work environment.

What are the key qualities of a successful Wheel Buffer?

The key qualities of a successful Wheel Buffer include attention to detail, mechanical aptitude, problem-solving skills, teamwork, and a commitment to safety.