Are you a seasoned Wheelabrator Operator seeking a new career path? Discover our professionally built Wheelabrator Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

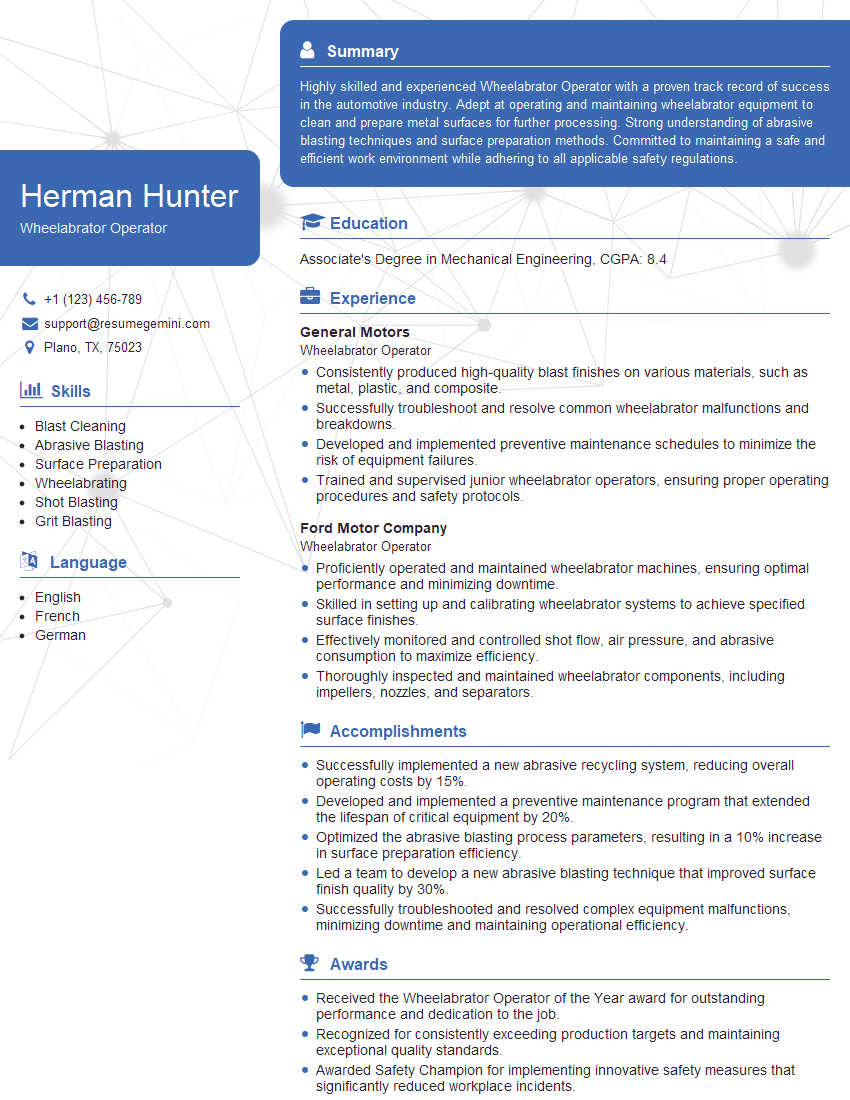

Herman Hunter

Wheelabrator Operator

Summary

Highly skilled and experienced Wheelabrator Operator with a proven track record of success in the automotive industry. Adept at operating and maintaining wheelabrator equipment to clean and prepare metal surfaces for further processing. Strong understanding of abrasive blasting techniques and surface preparation methods. Committed to maintaining a safe and efficient work environment while adhering to all applicable safety regulations.

Education

Associate’s Degree in Mechanical Engineering

February 2016

Skills

- Blast Cleaning

- Abrasive Blasting

- Surface Preparation

- Wheelabrating

- Shot Blasting

- Grit Blasting

Work Experience

Wheelabrator Operator

- Consistently produced high-quality blast finishes on various materials, such as metal, plastic, and composite.

- Successfully troubleshoot and resolve common wheelabrator malfunctions and breakdowns.

- Developed and implemented preventive maintenance schedules to minimize the risk of equipment failures.

- Trained and supervised junior wheelabrator operators, ensuring proper operating procedures and safety protocols.

Wheelabrator Operator

- Proficiently operated and maintained wheelabrator machines, ensuring optimal performance and minimizing downtime.

- Skilled in setting up and calibrating wheelabrator systems to achieve specified surface finishes.

- Effectively monitored and controlled shot flow, air pressure, and abrasive consumption to maximize efficiency.

- Thoroughly inspected and maintained wheelabrator components, including impellers, nozzles, and separators.

Accomplishments

- Successfully implemented a new abrasive recycling system, reducing overall operating costs by 15%.

- Developed and implemented a preventive maintenance program that extended the lifespan of critical equipment by 20%.

- Optimized the abrasive blasting process parameters, resulting in a 10% increase in surface preparation efficiency.

- Led a team to develop a new abrasive blasting technique that improved surface finish quality by 30%.

- Successfully troubleshooted and resolved complex equipment malfunctions, minimizing downtime and maintaining operational efficiency.

Awards

- Received the Wheelabrator Operator of the Year award for outstanding performance and dedication to the job.

- Recognized for consistently exceeding production targets and maintaining exceptional quality standards.

- Awarded Safety Champion for implementing innovative safety measures that significantly reduced workplace incidents.

- Honored for providing exceptional customer service and consistently meeting customer requirements.

Certificates

- National Association of Surface Finishing (NASF) Surface Preparation Technician (SPT)

- Society for Protective Coatings (SSPC) Certified Protective Coatings Inspector (CPI)

- American Welding Society (AWS) Certified Welder

- Occupational Safety and Health Administration (OSHA) 10-Hour Construction Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wheelabrator Operator

- Highlight your experience operating and maintaining wheelabrator equipment.

- Demonstrate your knowledge of abrasive blasting techniques and surface preparation methods.

- Emphasize your commitment to safety and your ability to work in a team environment.

- Include any relevant certifications or training that you have received.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Wheelabrator Operator Resume

- Operate and maintain wheelabrator equipment to clean and prepare metal surfaces for further processing.

- Select and adjust abrasive materials and blasting parameters to achieve desired surface finish.

- Monitor equipment performance and make necessary adjustments to ensure optimal operation.

- Inspect and maintain equipment to prevent breakdowns and ensure safe operation.

- Follow all applicable safety regulations and procedures.

- Maintain a clean and organized work area.

- Work with other team members to ensure efficient production flow.

Frequently Asked Questions (FAQ’s) For Wheelabrator Operator

What is a Wheelabrator Operator?

A Wheelabrator Operator is responsible for operating and maintaining wheelabrator equipment to clean and prepare metal surfaces for further processing.

What skills are required to be a Wheelabrator Operator?

Wheelabrator Operators must have a strong understanding of abrasive blasting techniques and surface preparation methods. They must also be able to operate and maintain wheelabrator equipment, and follow all applicable safety regulations.

What are the responsibilities of a Wheelabrator Operator?

Wheelabrator Operators are responsible for operating and maintaining wheelabrator equipment, selecting and adjusting abrasive materials and blasting parameters, monitoring equipment performance, inspecting and maintaining equipment, following all applicable safety regulations, maintaining a clean and organized work area, and working with other team members to ensure efficient production flow.

What is the work environment of a Wheelabrator Operator like?

Wheelabrator Operators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They must also be able to work in a team environment and follow all applicable safety regulations.

What are the career prospects for a Wheelabrator Operator?

Wheelabrator Operators can advance to supervisory or management positions. They may also specialize in a particular area of abrasive blasting, such as automotive or aerospace.

What is the salary range for a Wheelabrator Operator?

The salary range for a Wheelabrator Operator varies depending on experience, location, and company size. However, the median salary for a Wheelabrator Operator is around $40,000 per year.

How can I become a Wheelabrator Operator?

To become a Wheelabrator Operator, you can complete a formal training program or apprenticeship. You can also gain experience by working as a helper or assistant to a Wheelabrator Operator.