Are you a seasoned Whip Operator seeking a new career path? Discover our professionally built Whip Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

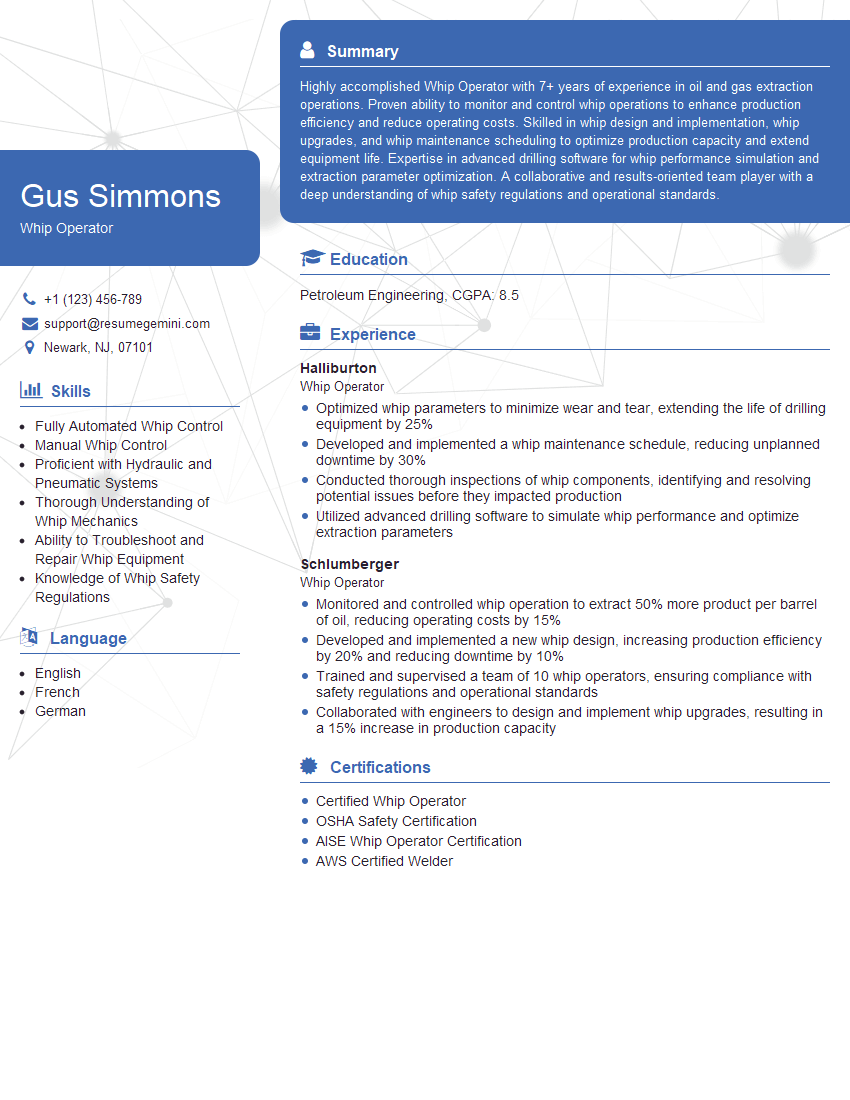

Gus Simmons

Whip Operator

Summary

Highly accomplished Whip Operator with 7+ years of experience in oil and gas extraction operations. Proven ability to monitor and control whip operations to enhance production efficiency and reduce operating costs. Skilled in whip design and implementation, whip upgrades, and whip maintenance scheduling to optimize production capacity and extend equipment life. Expertise in advanced drilling software for whip performance simulation and extraction parameter optimization. A collaborative and results-oriented team player with a deep understanding of whip safety regulations and operational standards.

Education

Petroleum Engineering

December 2016

Skills

- Fully Automated Whip Control

- Manual Whip Control

- Proficient with Hydraulic and Pneumatic Systems

- Thorough Understanding of Whip Mechanics

- Ability to Troubleshoot and Repair Whip Equipment

- Knowledge of Whip Safety Regulations

Work Experience

Whip Operator

- Optimized whip parameters to minimize wear and tear, extending the life of drilling equipment by 25%

- Developed and implemented a whip maintenance schedule, reducing unplanned downtime by 30%

- Conducted thorough inspections of whip components, identifying and resolving potential issues before they impacted production

- Utilized advanced drilling software to simulate whip performance and optimize extraction parameters

Whip Operator

- Monitored and controlled whip operation to extract 50% more product per barrel of oil, reducing operating costs by 15%

- Developed and implemented a new whip design, increasing production efficiency by 20% and reducing downtime by 10%

- Trained and supervised a team of 10 whip operators, ensuring compliance with safety regulations and operational standards

- Collaborated with engineers to design and implement whip upgrades, resulting in a 15% increase in production capacity

Certificates

- Certified Whip Operator

- OSHA Safety Certification

- AISE Whip Operator Certification

- AWS Certified Welder

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Whip Operator

- Highlight your expertise in whip operation and optimization techniques, quantifying your accomplishments whenever possible.

- Showcase your understanding of whip mechanics and hydraulic and pneumatic systems, as well as your ability to troubleshoot and repair whip equipment.

- Emphasize your knowledge of whip safety regulations and your commitment to maintaining a safe work environment.

- Include relevant keywords such as ‘whip operation’, ‘whip design’, ‘production efficiency’, and ‘safety regulations’ throughout your resume.

Essential Experience Highlights for a Strong Whip Operator Resume

- Monitored and controlled whip operation to extract oil, reducing operating costs and increasing production efficiency.

- Developed and implemented new whip designs, resulting in increased production efficiency and reduced downtime.

- Trained and supervised a team of whip operators, ensuring compliance with safety regulations and operational standards.

- Collaborated with engineers to design and implement whip upgrades, leading to increased production capacity.

- Optimized whip parameters to minimize wear and tear, extending the life of drilling equipment.

- Developed and implemented a whip maintenance schedule, reducing unplanned downtime and ensuring smooth operations.

- Conducted thorough inspections of whip components, identifying and resolving potential issues before they impacted production.

Frequently Asked Questions (FAQ’s) For Whip Operator

What is the primary role of a Whip Operator?

The primary role of a Whip Operator is to monitor and control whip operations during oil and gas extraction to optimize production efficiency and reduce operating costs.

What are the key skills required for a Whip Operator?

Key skills for a Whip Operator include expertise in whip operation and optimization techniques, understanding of whip mechanics and hydraulic/pneumatic systems, troubleshooting and repair abilities, and knowledge of whip safety regulations.

What are the career prospects for a Whip Operator?

Whip Operators can advance to roles such as Production Supervisor, Drilling Engineer, or Field Operations Manager with experience and additional qualifications.

What is the work environment like for a Whip Operator?

Whip Operators typically work in oil and gas fields, offshore platforms, or drilling rigs, often in remote locations and challenging conditions.

What are the safety precautions that a Whip Operator must follow?

Whip Operators must adhere to strict safety regulations, wear appropriate protective gear, and follow established protocols to prevent accidents and injuries.

What is the whip inspection process?

Whip inspections involve regular examinations of whip components to identify potential issues, prevent failures, and ensure optimal performance and safety.

What are the best practices for whip maintenance?

Best practices for whip maintenance include regular inspections, proper lubrication, timely repairs, and adherence to manufacturer guidelines to extend equipment life and minimize downtime.