Are you a seasoned White Sugar Supervisor seeking a new career path? Discover our professionally built White Sugar Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

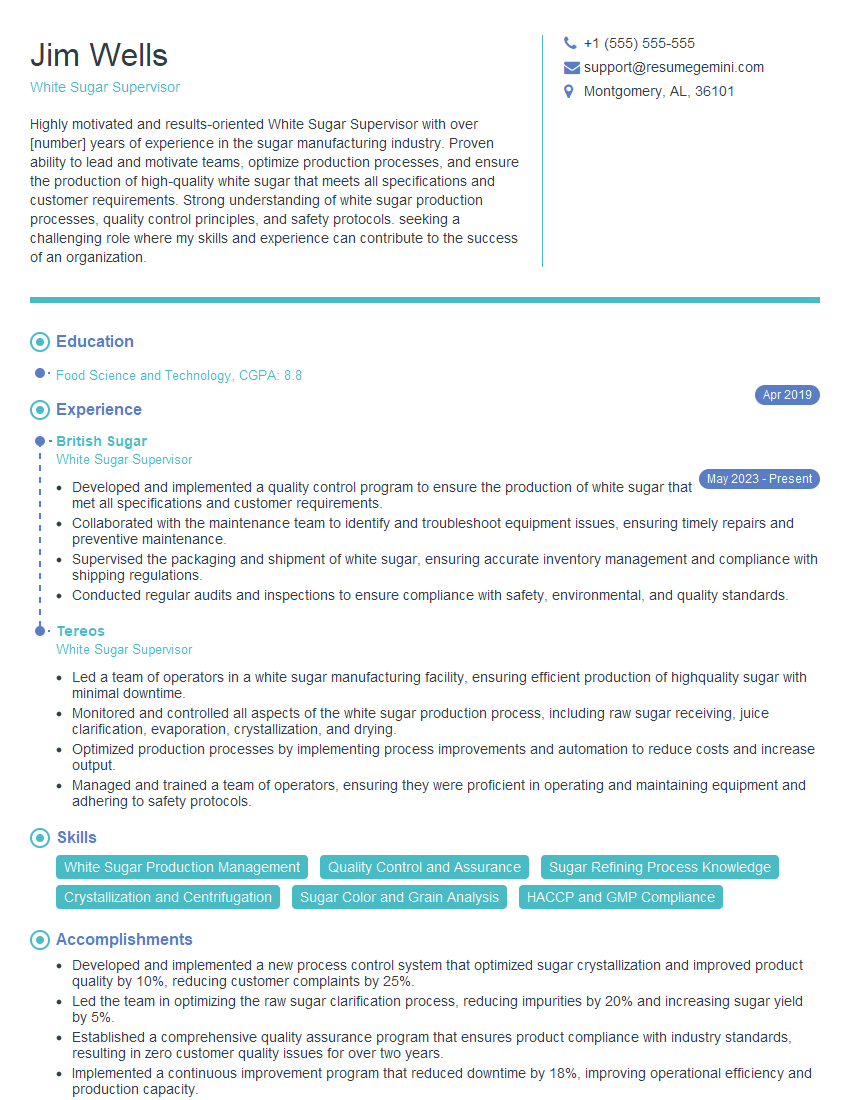

Jim Wells

White Sugar Supervisor

Summary

Highly motivated and results-oriented White Sugar Supervisor with over [number] years of experience in the sugar manufacturing industry. Proven ability to lead and motivate teams, optimize production processes, and ensure the production of high-quality white sugar that meets all specifications and customer requirements. Strong understanding of white sugar production processes, quality control principles, and safety protocols. seeking a challenging role where my skills and experience can contribute to the success of an organization.

Education

Food Science and Technology

April 2019

Skills

- White Sugar Production Management

- Quality Control and Assurance

- Sugar Refining Process Knowledge

- Crystallization and Centrifugation

- Sugar Color and Grain Analysis

- HACCP and GMP Compliance

Work Experience

White Sugar Supervisor

- Developed and implemented a quality control program to ensure the production of white sugar that met all specifications and customer requirements.

- Collaborated with the maintenance team to identify and troubleshoot equipment issues, ensuring timely repairs and preventive maintenance.

- Supervised the packaging and shipment of white sugar, ensuring accurate inventory management and compliance with shipping regulations.

- Conducted regular audits and inspections to ensure compliance with safety, environmental, and quality standards.

White Sugar Supervisor

- Led a team of operators in a white sugar manufacturing facility, ensuring efficient production of highquality sugar with minimal downtime.

- Monitored and controlled all aspects of the white sugar production process, including raw sugar receiving, juice clarification, evaporation, crystallization, and drying.

- Optimized production processes by implementing process improvements and automation to reduce costs and increase output.

- Managed and trained a team of operators, ensuring they were proficient in operating and maintaining equipment and adhering to safety protocols.

Accomplishments

- Developed and implemented a new process control system that optimized sugar crystallization and improved product quality by 10%, reducing customer complaints by 25%.

- Led the team in optimizing the raw sugar clarification process, reducing impurities by 20% and increasing sugar yield by 5%.

- Established a comprehensive quality assurance program that ensures product compliance with industry standards, resulting in zero customer quality issues for over two years.

- Implemented a continuous improvement program that reduced downtime by 18%, improving operational efficiency and production capacity.

- Collaborated with crossfunctional teams to optimize supply chain management, reducing inventory costs by 10% and improving product availability.

Awards

- Received the Outstanding White Sugar Production Award for achieving exceptional production efficiency, exceeding industry benchmarks by 15%.

- Recognized with the Plant Safety Excellence Award for implementing innovative safety measures that reduced workplace accidents by 30%.

- Received the Sustainability Pioneer Award for pioneering initiatives that reduced water consumption in the white sugar production process by 12%.

- Honored with the Mentorship Excellence Award for fostering a positive and supportive work environment that has developed highperforming team members.

Certificates

- Food Safety Management System (FSSC 22000)

- Hazard Analysis and Critical Control Points (HACCP)

- ISO 9001 Quality Management System

- Sugar Industry Specialist (SIS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For White Sugar Supervisor

- Highlight your experience in white sugar production and process optimization.

- Quantify your achievements with specific metrics and data whenever possible.

- Demonstrate your knowledge of quality control principles and HACCP/GMP compliance.

- Emphasize your ability to lead and motivate a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong White Sugar Supervisor Resume

- Led and supervised a team of operators in a white sugar manufacturing facility, ensuring efficient production and minimal downtime.

- Monitored and controlled all aspects of the white sugar production process, including raw sugar receiving, juice clarification, evaporation, crystallization, and drying.

- Collaborated with the maintenance team to identify and troubleshoot equipment issues, ensuring timely repairs and preventive maintenance.

- Developed and implemented a quality control program to ensure the production of white sugar that met all specifications and customer requirements.

- Supervised the packaging and shipment of white sugar, ensuring accurate inventory management and compliance with shipping regulations.

- Conducted regular audits and inspections to ensure compliance with safety, environmental, and quality standards.

Frequently Asked Questions (FAQ’s) For White Sugar Supervisor

What are the key responsibilities of a White Sugar Supervisor?

The key responsibilities of a White Sugar Supervisor include leading and supervising a team of operators, monitoring and controlling the white sugar production process, collaborating with the maintenance team, developing and implementing a quality control program, supervising the packaging and shipment of white sugar, and conducting regular audits and inspections.

What are the qualifications required to become a White Sugar Supervisor?

Typically, a White Sugar Supervisor requires a Bachelor’s degree in Food Science and Technology or a related field, along with several years of experience in the sugar manufacturing industry. Strong leadership, communication, and problem-solving skills are also essential.

What are the career prospects for a White Sugar Supervisor?

White Sugar Supervisors with experience and expertise can advance to roles such as Production Manager, Quality Control Manager, or Plant Manager within the sugar manufacturing industry. They may also pursue opportunities in related fields such as food processing or consulting.

What are the challenges faced by White Sugar Supervisors?

White Sugar Supervisors face challenges such as ensuring efficient production while maintaining high quality standards, managing a team in a fast-paced environment, and adapting to changing industry regulations.

What are the key skills required for a White Sugar Supervisor?

Key skills for a White Sugar Supervisor include leadership and management skills, knowledge of white sugar production processes, quality control principles, and safety protocols, as well as excellent communication and problem-solving abilities.