Are you a seasoned Whiting Machine Operator seeking a new career path? Discover our professionally built Whiting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

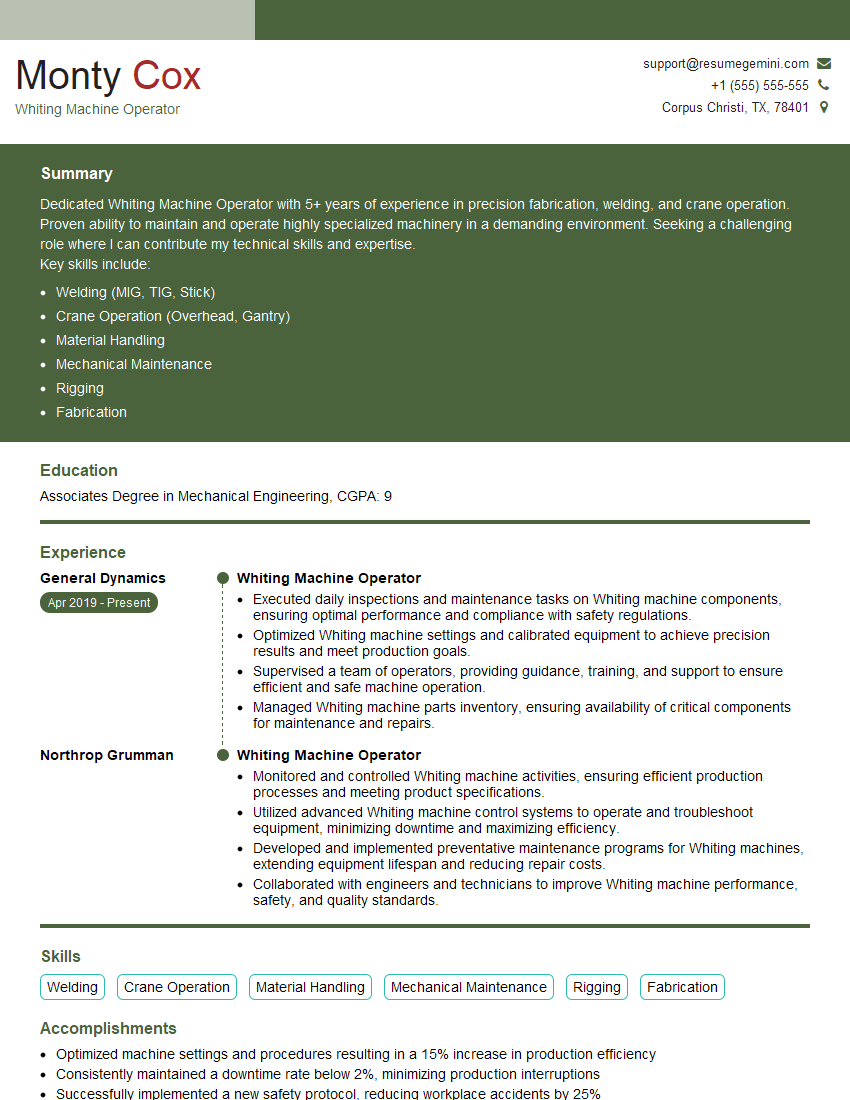

Monty Cox

Whiting Machine Operator

Summary

Dedicated Whiting Machine Operator with 5+ years of experience in precision fabrication, welding, and crane operation. Proven ability to maintain and operate highly specialized machinery in a demanding environment. Seeking a challenging role where I can contribute my technical skills and expertise.

Key skills include:

- Welding (MIG, TIG, Stick)

- Crane Operation (Overhead, Gantry)

- Material Handling

- Mechanical Maintenance

- Rigging

- Fabrication

Education

Associates Degree in Mechanical Engineering

March 2015

Skills

- Welding

- Crane Operation

- Material Handling

- Mechanical Maintenance

- Rigging

- Fabrication

Work Experience

Whiting Machine Operator

- Executed daily inspections and maintenance tasks on Whiting machine components, ensuring optimal performance and compliance with safety regulations.

- Optimized Whiting machine settings and calibrated equipment to achieve precision results and meet production goals.

- Supervised a team of operators, providing guidance, training, and support to ensure efficient and safe machine operation.

- Managed Whiting machine parts inventory, ensuring availability of critical components for maintenance and repairs.

Whiting Machine Operator

- Monitored and controlled Whiting machine activities, ensuring efficient production processes and meeting product specifications.

- Utilized advanced Whiting machine control systems to operate and troubleshoot equipment, minimizing downtime and maximizing efficiency.

- Developed and implemented preventative maintenance programs for Whiting machines, extending equipment lifespan and reducing repair costs.

- Collaborated with engineers and technicians to improve Whiting machine performance, safety, and quality standards.

Accomplishments

- Optimized machine settings and procedures resulting in a 15% increase in production efficiency

- Consistently maintained a downtime rate below 2%, minimizing production interruptions

- Successfully implemented a new safety protocol, reducing workplace accidents by 25%

- Proactively identified and resolved machine malfunctions, preventing potential equipment damage

- Trained and mentored 5 new Whiting Machine Operators, ensuring a high standard of performance

Awards

- Whiting Machine Operator of the Year Award

- Safety Excellence Award for Outstanding Performance in Operating Whiting Machines

- 1st Place in Whiting Machine Operator Skills Competition

Certificates

- Overhead Crane Operator Certification

- Forklift Operator Certification

- NCCCO Crane Operator Certification

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Whiting Machine Operator

- Highlight your welding certifications and experience with specific welding techniques used in the industry.

- Quantify your accomplishments by providing specific examples of projects or tasks you have successfully completed.

- Demonstrate your knowledge of Whiting machines by mentioning the specific models or types you have operated.

- Include any experience or training in rigging, crane operation, or other specialized skills relevant to the position.

Essential Experience Highlights for a Strong Whiting Machine Operator Resume

- Operate and maintain Whiting machines for precision fabrication and assembly tasks.

- Perform welding operations using MIG, TIG, and stick welding techniques.

- Utilize overhead and gantry cranes for material handling and machine setup.

- Conduct preventive maintenance and repairs on Whiting machines and associated equipment.

- Rig and secure materials and equipment for safe and efficient fabrication.

- Assist in the design and fabrication of custom machine components.

Frequently Asked Questions (FAQ’s) For Whiting Machine Operator

What is a Whiting machine?

A Whiting machine is a specialized type of industrial machinery used for heavy-duty fabrication and assembly tasks. It is typically used in industries such as shipbuilding, aerospace, and construction.

What are the key skills required to be a successful Whiting Machine Operator?

Key skills include welding, crane operation, material handling, mechanical maintenance, rigging, and fabrication.

What are the career prospects for a Whiting Machine Operator?

With experience and certifications, Whiting Machine Operators can advance to supervisory roles or become welding engineers or fabricators.

What are the safety precautions that must be taken when operating a Whiting machine?

Safety precautions include wearing appropriate personal protective equipment, following proper lockout/tagout procedures, and adhering to all safety regulations.

What is the work environment like for a Whiting Machine Operator?

Whiting Machine Operators typically work in industrial settings, such as fabrication shops or manufacturing facilities. The work can be physically demanding and requires attention to detail and safety.

What are the typical salary expectations for a Whiting Machine Operator?

Salary expectations vary depending on experience, location, and industry. According to Indeed, the average salary for a Whiting Machine Operator in the United States is around $65,000 per year.

What are the educational requirements to become a Whiting Machine Operator?

While formal education is not always required, many Whiting Machine Operators have an associate degree in mechanical engineering or a related field.