Are you a seasoned Winder Contort Operator seeking a new career path? Discover our professionally built Winder Contort Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

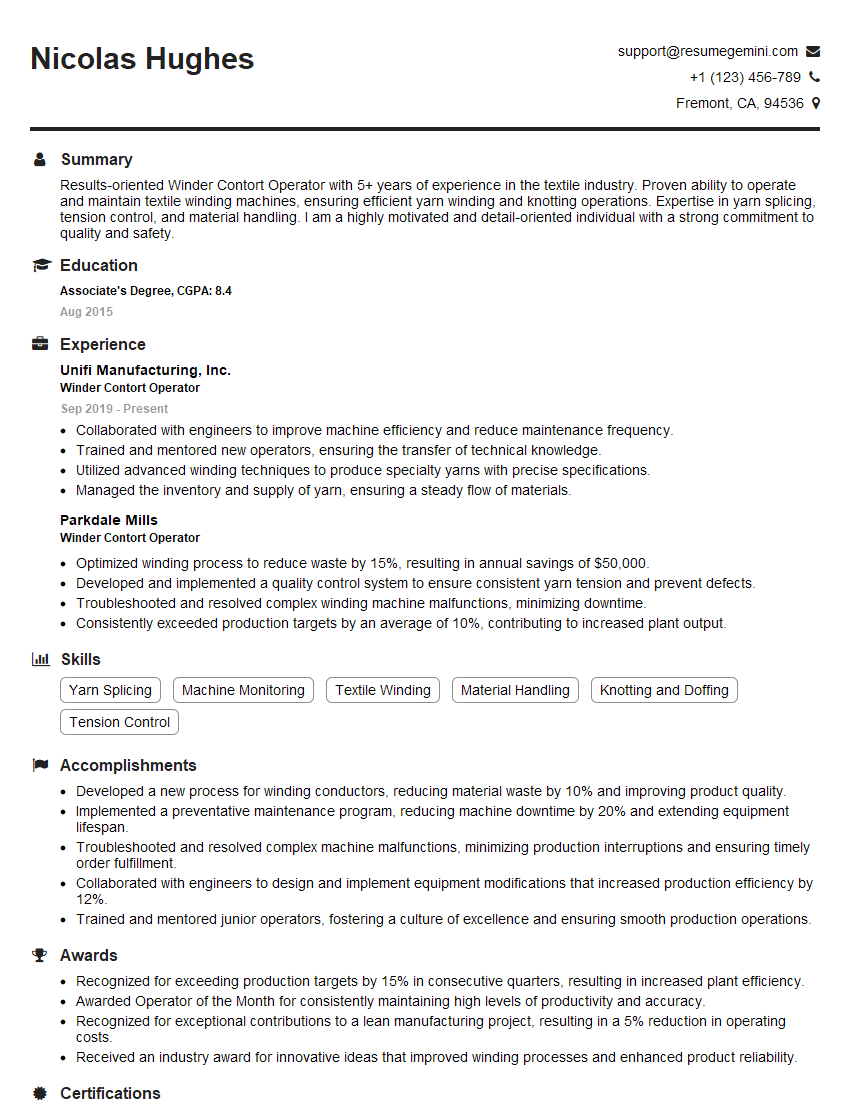

Nicolas Hughes

Winder Contort Operator

Summary

Results-oriented Winder Contort Operator with 5+ years of experience in the textile industry. Proven ability to operate and maintain textile winding machines, ensuring efficient yarn winding and knotting operations. Expertise in yarn splicing, tension control, and material handling. I am a highly motivated and detail-oriented individual with a strong commitment to quality and safety.

Education

Associate’s Degree

August 2015

Skills

- Yarn Splicing

- Machine Monitoring

- Textile Winding

- Material Handling

- Knotting and Doffing

- Tension Control

Work Experience

Winder Contort Operator

- Collaborated with engineers to improve machine efficiency and reduce maintenance frequency.

- Trained and mentored new operators, ensuring the transfer of technical knowledge.

- Utilized advanced winding techniques to produce specialty yarns with precise specifications.

- Managed the inventory and supply of yarn, ensuring a steady flow of materials.

Winder Contort Operator

- Optimized winding process to reduce waste by 15%, resulting in annual savings of $50,000.

- Developed and implemented a quality control system to ensure consistent yarn tension and prevent defects.

- Troubleshooted and resolved complex winding machine malfunctions, minimizing downtime.

- Consistently exceeded production targets by an average of 10%, contributing to increased plant output.

Accomplishments

- Developed a new process for winding conductors, reducing material waste by 10% and improving product quality.

- Implemented a preventative maintenance program, reducing machine downtime by 20% and extending equipment lifespan.

- Troubleshooted and resolved complex machine malfunctions, minimizing production interruptions and ensuring timely order fulfillment.

- Collaborated with engineers to design and implement equipment modifications that increased production efficiency by 12%.

- Trained and mentored junior operators, fostering a culture of excellence and ensuring smooth production operations.

Awards

- Recognized for exceeding production targets by 15% in consecutive quarters, resulting in increased plant efficiency.

- Awarded Operator of the Month for consistently maintaining high levels of productivity and accuracy.

- Recognized for exceptional contributions to a lean manufacturing project, resulting in a 5% reduction in operating costs.

- Received an industry award for innovative ideas that improved winding processes and enhanced product reliability.

Certificates

- Winder Contort Operator Certification (WCOC)

- Textile Manufacturing Technician Certification (TMTC)

- Yarn Quality Control Certification (YQCC)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winder Contort Operator

- Highlight your experience and skills in yarn splicing, machine monitoring, and textile winding.

- Quantify your accomplishments and provide specific examples of your contributions.

- Emphasize your attention to detail, quality assurance, and commitment to safety.

- Proofread your resume carefully to ensure there are no errors.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Winder Contort Operator Resume

- Operate and maintain textile winding machines to produce high-quality yarn products.

- Monitor machine performance, identify and resolve any issues promptly.

- Perform yarn splicing, knotting, and doffing operations to ensure continuous production.

- Control yarn tension to prevent breakage and maintain yarn quality.

- Handle and transport materials safely and efficiently.

- Maintain a clean and organized work area, adhering to safety regulations.

- Work collaboratively with other team members to achieve production goals.

Frequently Asked Questions (FAQ’s) For Winder Contort Operator

What is the role of a Winder Contort Operator?

A Winder Contort Operator is responsible for operating and maintaining textile winding machines to produce high-quality yarn products. They monitor machine performance, perform yarn splicing and knotting, control yarn tension, and handle materials safely.

What skills are required to be a successful Winder Contort Operator?

Successful Winder Contort Operators typically have experience in yarn splicing, machine monitoring, textile winding, material handling, knotting, doffing, and tension control.

What is the work environment of a Winder Contort Operator like?

Winder Contort Operators typically work in a manufacturing environment, operating textile winding machines in a fast-paced and demanding setting.

What are the career prospects for a Winder Contort Operator?

With experience and additional training, Winder Contort Operators may advance to supervisory or management roles within the textile industry.

What is the average salary for a Winder Contort Operator?

The average salary for a Winder Contort Operator varies depending on experience, location, and company size, but is typically around $15-$20 per hour.

What are the benefits of working as a Winder Contort Operator?

Winder Contort Operators can enjoy benefits such as health insurance, paid time off, and opportunities for overtime pay.