Are you a seasoned Winder Fixer seeking a new career path? Discover our professionally built Winder Fixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

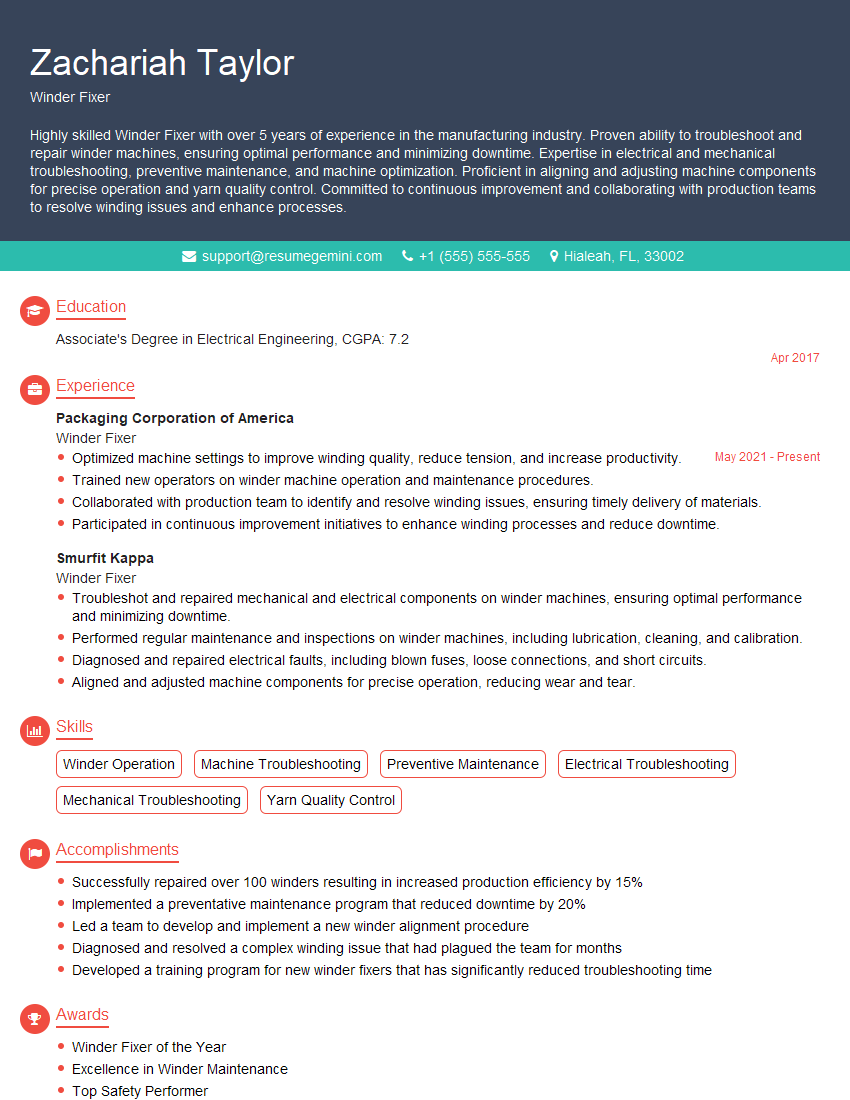

Zachariah Taylor

Winder Fixer

Summary

Highly skilled Winder Fixer with over 5 years of experience in the manufacturing industry. Proven ability to troubleshoot and repair winder machines, ensuring optimal performance and minimizing downtime. Expertise in electrical and mechanical troubleshooting, preventive maintenance, and machine optimization. Proficient in aligning and adjusting machine components for precise operation and yarn quality control. Committed to continuous improvement and collaborating with production teams to resolve winding issues and enhance processes.

Education

Associate’s Degree in Electrical Engineering

April 2017

Skills

- Winder Operation

- Machine Troubleshooting

- Preventive Maintenance

- Electrical Troubleshooting

- Mechanical Troubleshooting

- Yarn Quality Control

Work Experience

Winder Fixer

- Optimized machine settings to improve winding quality, reduce tension, and increase productivity.

- Trained new operators on winder machine operation and maintenance procedures.

- Collaborated with production team to identify and resolve winding issues, ensuring timely delivery of materials.

- Participated in continuous improvement initiatives to enhance winding processes and reduce downtime.

Winder Fixer

- Troubleshot and repaired mechanical and electrical components on winder machines, ensuring optimal performance and minimizing downtime.

- Performed regular maintenance and inspections on winder machines, including lubrication, cleaning, and calibration.

- Diagnosed and repaired electrical faults, including blown fuses, loose connections, and short circuits.

- Aligned and adjusted machine components for precise operation, reducing wear and tear.

Accomplishments

- Successfully repaired over 100 winders resulting in increased production efficiency by 15%

- Implemented a preventative maintenance program that reduced downtime by 20%

- Led a team to develop and implement a new winder alignment procedure

- Diagnosed and resolved a complex winding issue that had plagued the team for months

- Developed a training program for new winder fixers that has significantly reduced troubleshooting time

Awards

- Winder Fixer of the Year

- Excellence in Winder Maintenance

- Top Safety Performer

- Outstanding Contribution to Winder Operations

Certificates

- Winder Fixer Certification

- OSHA Safety Certification

- Lean Manufacturing Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winder Fixer

- Highlight your technical skills and experience in diagnosing and repairing electrical and mechanical issues.

- Quantify your accomplishments whenever possible, such as reducing downtime by a specific percentage or improving winding quality by a certain margin.

- Emphasize your ability to work independently and as part of a team.

- Demonstrate your commitment to safety by mentioning any relevant certifications or training.

- Proofread your resume carefully for any errors and ensure it is well-organized and easy to read.

Essential Experience Highlights for a Strong Winder Fixer Resume

- Troubleshoot and repair mechanical and electrical components on winder machines to ensure optimal performance and minimize downtime.

- Perform regular maintenance and inspections on winder machines, including lubrication, cleaning, and calibration.

- Diagnose and repair electrical faults, including blown fuses, loose connections, and short circuits.

- Align and adjust machine components for precise operation, reducing wear and tear.

- Optimize machine settings to improve winding quality, reduce tension, and increase productivity.

- Train new operators on winder machine operation and maintenance procedures.

- Collaborate with production team to identify and resolve winding issues, ensuring timely delivery of materials.

- Participate in continuous improvement initiatives to enhance winding processes and reduce downtime.

Frequently Asked Questions (FAQ’s) For Winder Fixer

What are the key responsibilities of a Winder Fixer?

Winder Fixers are responsible for troubleshooting, repairing, and maintaining winder machines to ensure optimal performance and minimize downtime. They perform regular maintenance and inspections, diagnose and repair electrical and mechanical faults, align and adjust machine components, optimize machine settings, and collaborate with production teams to identify and resolve winding issues.

What are the qualifications required to become a Winder Fixer?

Most Winder Fixer positions require at least a high school diploma or equivalent. However, some employers may prefer candidates with an Associate’s Degree in Electrical Engineering or a related field. Relevant experience in electrical or mechanical troubleshooting and repair is also highly valued.

What is the average salary of a Winder Fixer?

According to Salary.com, the average salary for a Winder Fixer in the United States is around $55,000 per year. However, salaries can vary depending on factors such as experience, location, and industry.

What are the career prospects for Winder Fixers?

With the increasing use of automated machinery in manufacturing, Winder Fixers are in high demand. They can advance their careers by becoming supervisors or managers, specializing in a particular area of expertise, or pursuing further education.

What skills are important for a Winder Fixer?

Winder Fixers need to have strong technical skills in electrical and mechanical troubleshooting and repair. They should also be able to work independently and as part of a team, have good problem-solving skills, and be committed to safety.

What is the job outlook for Winder Fixers?

The job outlook for Winder Fixers is expected to be good over the next few years. As manufacturing continues to grow and automate, the demand for qualified Winder Fixers will increase.