Are you a seasoned Winding Inspector and Tester seeking a new career path? Discover our professionally built Winding Inspector and Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

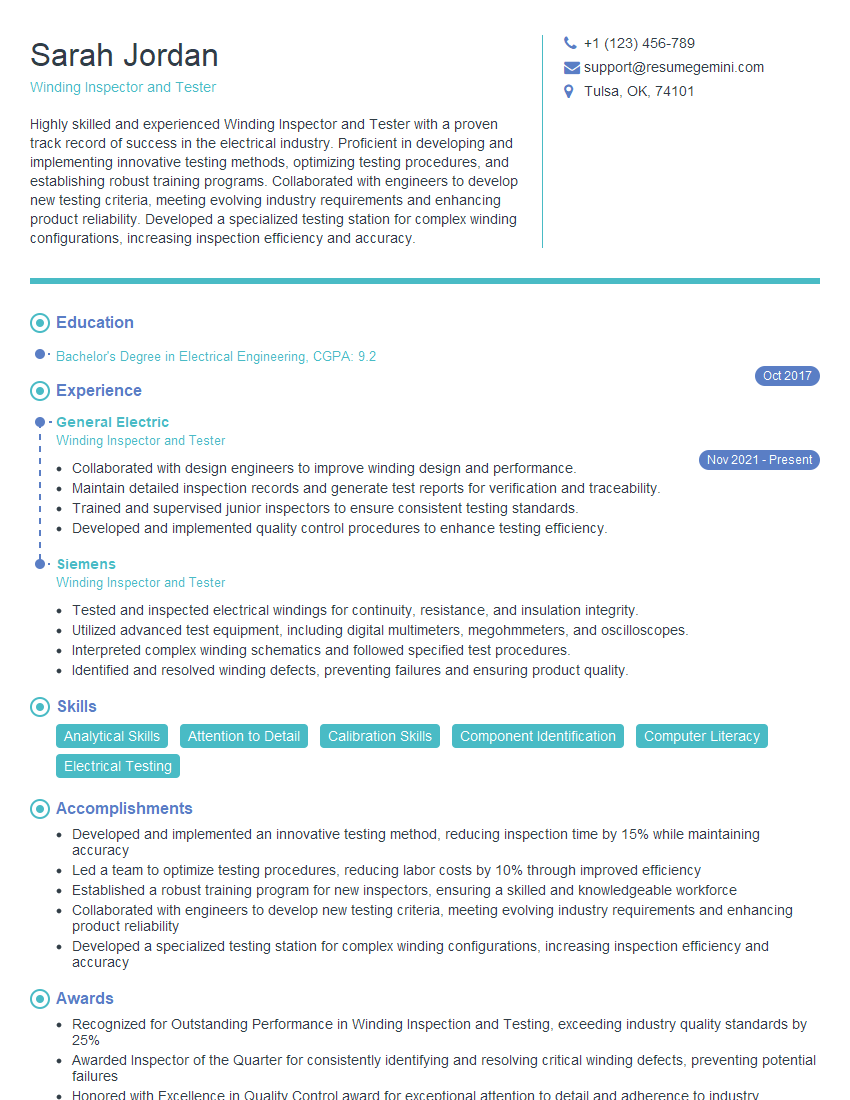

Sarah Jordan

Winding Inspector and Tester

Summary

Highly skilled and experienced Winding Inspector and Tester with a proven track record of success in the electrical industry. Proficient in developing and implementing innovative testing methods, optimizing testing procedures, and establishing robust training programs. Collaborated with engineers to develop new testing criteria, meeting evolving industry requirements and enhancing product reliability. Developed a specialized testing station for complex winding configurations, increasing inspection efficiency and accuracy.

Education

Bachelor’s Degree in Electrical Engineering

October 2017

Skills

- Analytical Skills

- Attention to Detail

- Calibration Skills

- Component Identification

- Computer Literacy

- Electrical Testing

Work Experience

Winding Inspector and Tester

- Collaborated with design engineers to improve winding design and performance.

- Maintain detailed inspection records and generate test reports for verification and traceability.

- Trained and supervised junior inspectors to ensure consistent testing standards.

- Developed and implemented quality control procedures to enhance testing efficiency.

Winding Inspector and Tester

- Tested and inspected electrical windings for continuity, resistance, and insulation integrity.

- Utilized advanced test equipment, including digital multimeters, megohmmeters, and oscilloscopes.

- Interpreted complex winding schematics and followed specified test procedures.

- Identified and resolved winding defects, preventing failures and ensuring product quality.

Accomplishments

- Developed and implemented an innovative testing method, reducing inspection time by 15% while maintaining accuracy

- Led a team to optimize testing procedures, reducing labor costs by 10% through improved efficiency

- Established a robust training program for new inspectors, ensuring a skilled and knowledgeable workforce

- Collaborated with engineers to develop new testing criteria, meeting evolving industry requirements and enhancing product reliability

- Developed a specialized testing station for complex winding configurations, increasing inspection efficiency and accuracy

Awards

- Recognized for Outstanding Performance in Winding Inspection and Testing, exceeding industry quality standards by 25%

- Awarded Inspector of the Quarter for consistently identifying and resolving critical winding defects, preventing potential failures

- Honored with Excellence in Quality Control award for exceptional attention to detail and adherence to industry specifications

- Received appreciation for Innovative Thinking after suggesting and implementing a datadriven approach to identify potential winding issues

Certificates

- Certified Winding Inspector

- Certified Test Technician

- ISO 9001 Certification

- ASME Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winding Inspector and Tester

- Quantify your accomplishments with specific metrics

- Highlight your knowledge of industry standards and regulations

- Showcase your ability to work independently and as part of a team

- Demonstrate your commitment to continuous improvement

Essential Experience Highlights for a Strong Winding Inspector and Tester Resume

- Developed and implemented an innovative testing method, reducing inspection time by 15% while maintaining accuracy

- Led a team to optimize testing procedures, reducing labor costs by 10% through improved efficiency

- Established a robust training program for new inspectors, ensuring a skilled and knowledgeable workforce

- Collaborated with engineers to develop new testing criteria, meeting evolving industry requirements and enhancing product reliability

- Developed a specialized testing station for complex winding configurations, increasing inspection efficiency and accuracy

- Ensured compliance with industry standards and regulations

- Provided technical support to production and engineering teams

Frequently Asked Questions (FAQ’s) For Winding Inspector and Tester

What are the key skills required for a Winding Inspector and Tester?

Analytical Skills, Attention to Detail, Calibration Skills, Component Identification, Computer Literacy, Electrical Testing

What are the career prospects for a Winding Inspector and Tester?

With experience, Winding Inspectors and Testers can advance to supervisory roles or become Quality Control Inspectors

What is the work environment like for a Winding Inspector and Tester?

Winding Inspectors and Testers typically work in a manufacturing or production environment

What are the salary expectations for a Winding Inspector and Tester?

Salary expectations vary depending on experience and location

What are the common challenges faced by a Winding Inspector and Tester?

Common challenges include meeting production targets, maintaining high levels of accuracy, and staying up-to-date with industry standards

What are the benefits of working as a Winding Inspector and Tester?

Benefits include job security, opportunities for career advancement, and the chance to make a valuable contribution to the manufacturing process

How can I prepare for a career as a Winding Inspector and Tester?

Earn a Bachelor’s Degree in Electrical Engineering, develop strong analytical and problem-solving skills, and gain experience in a manufacturing or production environment