Are you a seasoned Winding Lathe Operator seeking a new career path? Discover our professionally built Winding Lathe Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

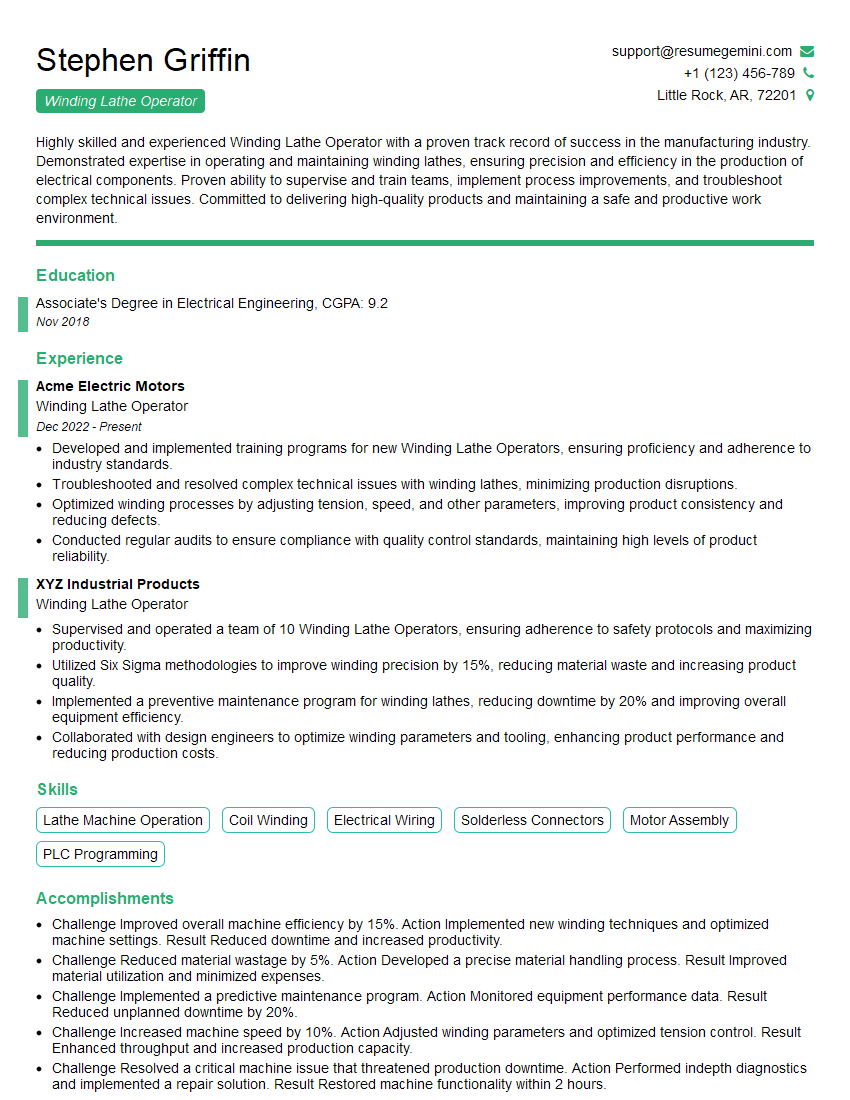

Stephen Griffin

Winding Lathe Operator

Summary

Highly skilled and experienced Winding Lathe Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in operating and maintaining winding lathes, ensuring precision and efficiency in the production of electrical components. Proven ability to supervise and train teams, implement process improvements, and troubleshoot complex technical issues. Committed to delivering high-quality products and maintaining a safe and productive work environment.

Education

Associate’s Degree in Electrical Engineering

November 2018

Skills

- Lathe Machine Operation

- Coil Winding

- Electrical Wiring

- Solderless Connectors

- Motor Assembly

- PLC Programming

Work Experience

Winding Lathe Operator

- Developed and implemented training programs for new Winding Lathe Operators, ensuring proficiency and adherence to industry standards.

- Troubleshooted and resolved complex technical issues with winding lathes, minimizing production disruptions.

- Optimized winding processes by adjusting tension, speed, and other parameters, improving product consistency and reducing defects.

- Conducted regular audits to ensure compliance with quality control standards, maintaining high levels of product reliability.

Winding Lathe Operator

- Supervised and operated a team of 10 Winding Lathe Operators, ensuring adherence to safety protocols and maximizing productivity.

- Utilized Six Sigma methodologies to improve winding precision by 15%, reducing material waste and increasing product quality.

- Implemented a preventive maintenance program for winding lathes, reducing downtime by 20% and improving overall equipment efficiency.

- Collaborated with design engineers to optimize winding parameters and tooling, enhancing product performance and reducing production costs.

Accomplishments

- Challenge Improved overall machine efficiency by 15%. Action Implemented new winding techniques and optimized machine settings. Result Reduced downtime and increased productivity.

- Challenge Reduced material wastage by 5%. Action Developed a precise material handling process. Result Improved material utilization and minimized expenses.

- Challenge Implemented a predictive maintenance program. Action Monitored equipment performance data. Result Reduced unplanned downtime by 20%.

- Challenge Increased machine speed by 10%. Action Adjusted winding parameters and optimized tension control. Result Enhanced throughput and increased production capacity.

- Challenge Resolved a critical machine issue that threatened production downtime. Action Performed indepth diagnostics and implemented a repair solution. Result Restored machine functionality within 2 hours.

Awards

- Received the Operator of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for innovative contributions to winding processes, resulting in a 10% reduction in production costs.

- Awarded for achieving 99.9% accuracy in quality control inspections, ensuring adherence to strict industry standards.

- Recognized for developing a training program that enhanced operator skills and increased production output.

Certificates

- Certified Winding Lathe Operator (CWLO)

- National Coalition of Winding Industries (NCWI)

- PMMI ProSource

- IPC-A-610 Acceptability of Electronic Assemblies

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winding Lathe Operator

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your work.

- Highlight your technical skills: Emphasize your proficiency in operating and maintaining winding lathes, as well as your knowledge of electrical wiring, solderless connectors, motor assembly, and PLC programming.

- Showcase your leadership abilities: If you have experience supervising a team, highlight your skills in motivating, training, and developing your team members.

- Obtain industry certifications: Consider obtaining certifications from relevant organizations, such as the National Institute for Metalworking Skills (NIMS), to enhance your credibility and demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Winding Lathe Operator Resume

- Supervise and lead a team of Winding Lathe Operators, ensuring adherence to safety protocols and maximizing productivity.

- Utilize Six Sigma methodologies to improve winding precision, reduce material waste, and enhance product quality.

- Implement and manage a preventive maintenance program for winding lathes, reducing downtime and improving overall equipment efficiency.

- Collaborate with design engineers to optimize winding parameters and tooling, boosting product performance and reducing production costs.

- Develop and implement training programs for new Winding Lathe Operators, ensuring proficiency and adherence to industry standards.

- Troubleshoot and resolve complex technical issues with winding lathes, minimizing production disruptions and maintaining operational efficiency.

- Optimize winding processes by adjusting tension, speed, and other parameters, enhancing product consistency and minimizing defects.

Frequently Asked Questions (FAQ’s) For Winding Lathe Operator

What is the primary role of a Winding Lathe Operator?

A Winding Lathe Operator is responsible for operating and maintaining winding lathes used in the production of electrical components. They ensure precision and efficiency in the winding process, contributing to the overall quality and reliability of the manufactured products.

What are the essential skills required for a Winding Lathe Operator?

Essential skills for a Winding Lathe Operator include proficiency in operating and maintaining winding lathes, as well as a solid understanding of electrical wiring, solderless connectors, motor assembly, and PLC programming. Additionally, strong attention to detail, problem-solving abilities, and a commitment to safety are crucial.

What are the career prospects for a Winding Lathe Operator?

Winding Lathe Operators can advance their careers by gaining experience and developing their skills. They can progress to supervisory roles, such as Lead Operator or Production Supervisor, or specialize in specific areas of winding technology. With additional training and education, they may also transition into related fields, such as electrical engineering or manufacturing management.

What is the work environment like for a Winding Lathe Operator?

Winding Lathe Operators typically work in manufacturing facilities, operating winding lathes in production lines. The work environment can be noisy and involve exposure to electrical equipment and materials. Adherence to safety protocols and proper handling of equipment are essential to maintain a safe and productive work environment.

What industries employ Winding Lathe Operators?

Winding Lathe Operators are employed in various industries that manufacture electrical components and products. These industries include electrical equipment manufacturing, automotive, aerospace, and electronics. They play a vital role in the production of motors, transformers, generators, and other electrical devices.

How can I prepare for a career as a Winding Lathe Operator?

To prepare for a career as a Winding Lathe Operator, consider obtaining an Associate’s Degree in Electrical Engineering or a related field. Additionally, seek opportunities to gain hands-on experience through internships or apprenticeships. Develop a strong understanding of electrical principles, winding techniques, and safety protocols. Stay updated with the latest advancements in winding technology and industry best practices.

What are the key qualities of a successful Winding Lathe Operator?

Successful Winding Lathe Operators possess a strong attention to detail, precision, and accuracy. They are?? in operating and maintaining winding lathes, and have a deep understanding of electrical wiring, solderless connectors, motor assembly, and PLC programming. They are also effective communicators, can work independently and as part of a team, and are committed to safety and quality.

Is there a high demand for Winding Lathe Operators?

The demand for Winding Lathe Operators varies depending on the industry and economic conditions. However, skilled Winding Lathe Operators with a strong understanding of electrical principles and winding techniques are generally in demand. The manufacturing sector, particularly in industries such as electrical equipment manufacturing, automotive, and aerospace, often seeks qualified Winding Lathe Operators to support their production processes.