Are you a seasoned Wire Rigger seeking a new career path? Discover our professionally built Wire Rigger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

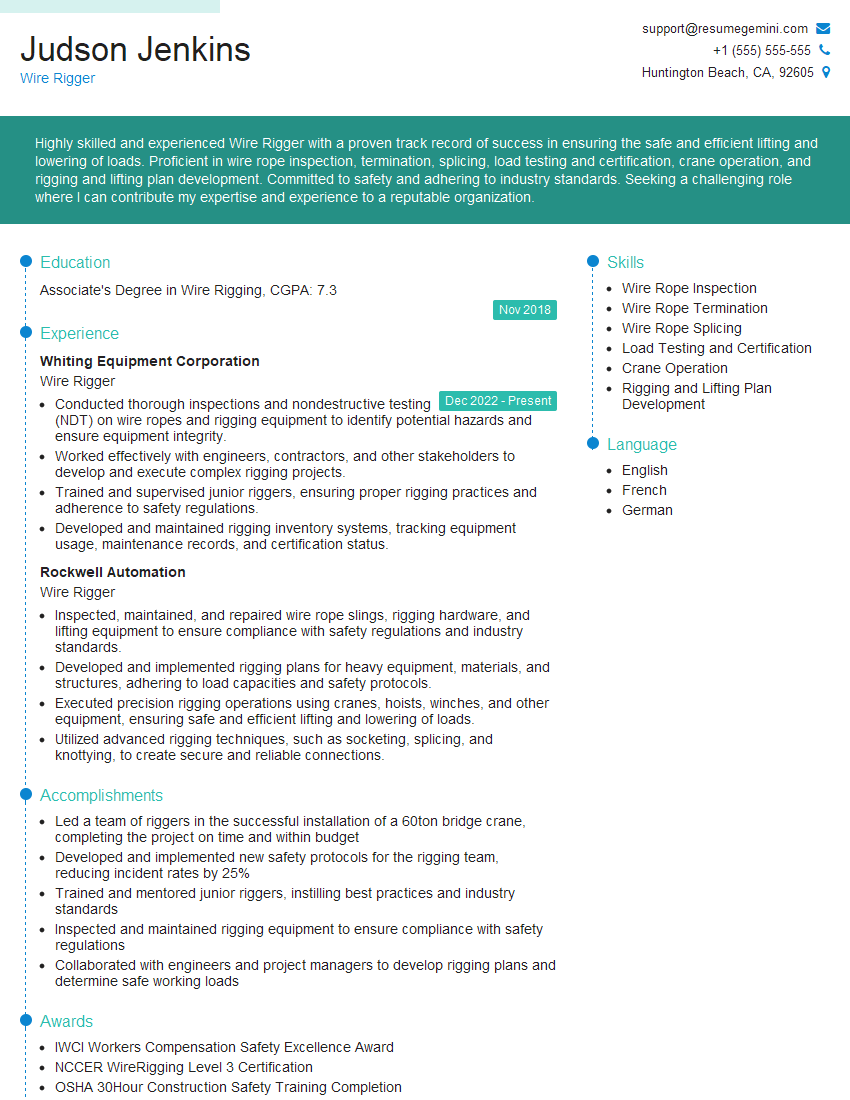

Judson Jenkins

Wire Rigger

Summary

Highly skilled and experienced Wire Rigger with a proven track record of success in ensuring the safe and efficient lifting and lowering of loads. Proficient in wire rope inspection, termination, splicing, load testing and certification, crane operation, and rigging and lifting plan development. Committed to safety and adhering to industry standards. Seeking a challenging role where I can contribute my expertise and experience to a reputable organization.

Education

Associate’s Degree in Wire Rigging

November 2018

Skills

- Wire Rope Inspection

- Wire Rope Termination

- Wire Rope Splicing

- Load Testing and Certification

- Crane Operation

- Rigging and Lifting Plan Development

Work Experience

Wire Rigger

- Conducted thorough inspections and nondestructive testing (NDT) on wire ropes and rigging equipment to identify potential hazards and ensure equipment integrity.

- Worked effectively with engineers, contractors, and other stakeholders to develop and execute complex rigging projects.

- Trained and supervised junior riggers, ensuring proper rigging practices and adherence to safety regulations.

- Developed and maintained rigging inventory systems, tracking equipment usage, maintenance records, and certification status.

Wire Rigger

- Inspected, maintained, and repaired wire rope slings, rigging hardware, and lifting equipment to ensure compliance with safety regulations and industry standards.

- Developed and implemented rigging plans for heavy equipment, materials, and structures, adhering to load capacities and safety protocols.

- Executed precision rigging operations using cranes, hoists, winches, and other equipment, ensuring safe and efficient lifting and lowering of loads.

- Utilized advanced rigging techniques, such as socketing, splicing, and knottying, to create secure and reliable connections.

Accomplishments

- Led a team of riggers in the successful installation of a 60ton bridge crane, completing the project on time and within budget

- Developed and implemented new safety protocols for the rigging team, reducing incident rates by 25%

- Trained and mentored junior riggers, instilling best practices and industry standards

- Inspected and maintained rigging equipment to ensure compliance with safety regulations

- Collaborated with engineers and project managers to develop rigging plans and determine safe working loads

Awards

- IWCI Workers Compensation Safety Excellence Award

- NCCER WireRigging Level 3 Certification

- OSHA 30Hour Construction Safety Training Completion

Certificates

- CWI (Certified Welding Inspector)

- AWS (American Welding Society)

- NCCCO (National Commission for the Certification of Crane Operators)

- OSHA (Occupational Safety and Health Administration)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Rigger

Highlight your safety record and adherence to industry standards.

Demonstrate your proficiency in various rigging techniques.

Showcase your experience in planning and executing complex rigging projects.

Quantify your accomplishments whenever possible.

Obtain industry certifications to enhance your credibility.

Essential Experience Highlights for a Strong Wire Rigger Resume

- Inspected, maintained, and repaired wire rope slings, rigging hardware, and lifting equipment to ensure compliance with safety regulations and industry standards.

- Developed and implemented rigging plans for heavy equipment, materials, and structures, adhering to load capacities and safety protocols.

- Executed precision rigging operations using cranes, hoists, winches, and other equipment, ensuring safe and efficient lifting and lowering of loads.

- Utilized advanced rigging techniques, such as socketing, splicing, and knottying, to create secure and reliable connections.

- Conducted thorough inspections and non-destructive testing (NDT) on wire ropes and rigging equipment to identify potential hazards and ensure equipment integrity.

- Worked effectively with engineers, contractors, and other stakeholders to develop and execute complex rigging projects.

- Trained and supervised junior riggers, ensuring proper rigging practices and adherence to safety regulations.

Frequently Asked Questions (FAQ’s) For Wire Rigger

What is the role of a Wire Rigger?

A Wire Rigger is responsible for the safe and efficient lifting and lowering of loads using wire rope slings, rigging hardware, and lifting equipment. They inspect, maintain, and repair rigging equipment, develop rigging plans, and execute rigging operations.

What skills are required for a Wire Rigger?

Wire Riggers require proficiency in wire rope inspection, termination, splicing, load testing and certification, crane operation, and rigging and lifting plan development. They must also have a strong understanding of safety regulations and industry standards.

What industries employ Wire Riggers?

Wire Riggers are employed in various industries, including construction, manufacturing, shipbuilding, and mining. They work on projects that require the lifting and lowering of heavy equipment, materials, and structures.

What is the career path for a Wire Rigger?

Wire Riggers can advance their careers by becoming lead riggers, supervisors, or safety inspectors. They can also specialize in specific areas, such as crane operation or heavy rigging.

How can I become a Wire Rigger?

To become a Wire Rigger, you can obtain an associate’s degree in wire rigging or a related field, complete an apprenticeship program, or gain experience through on-the-job training.

What are the safety regulations that Wire Riggers must follow?

Wire Riggers must follow safety regulations set by OSHA and other industry organizations. These regulations cover topics such as equipment inspection, load handling, and personal protective equipment.