Are you a seasoned Wire Stripping Machine Operator seeking a new career path? Discover our professionally built Wire Stripping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

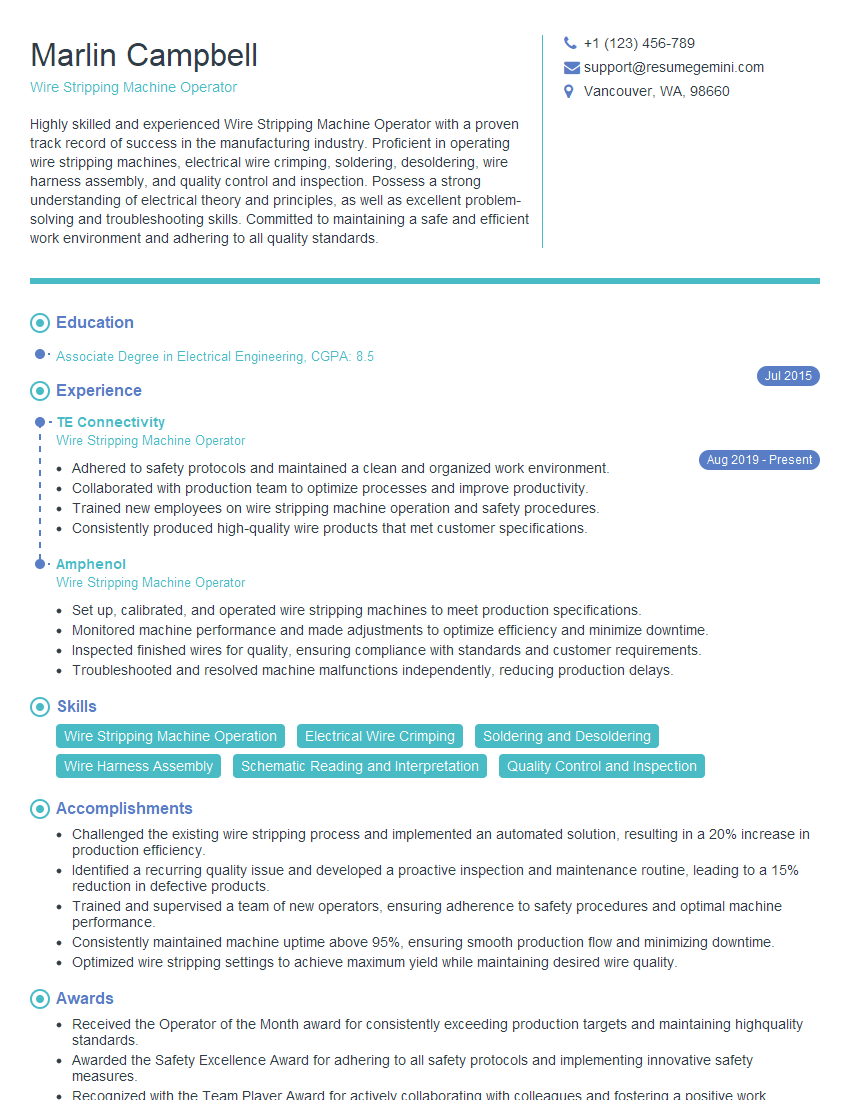

Marlin Campbell

Wire Stripping Machine Operator

Summary

Highly skilled and experienced Wire Stripping Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating wire stripping machines, electrical wire crimping, soldering, desoldering, wire harness assembly, and quality control and inspection. Possess a strong understanding of electrical theory and principles, as well as excellent problem-solving and troubleshooting skills. Committed to maintaining a safe and efficient work environment and adhering to all quality standards.

Education

Associate Degree in Electrical Engineering

July 2015

Skills

- Wire Stripping Machine Operation

- Electrical Wire Crimping

- Soldering and Desoldering

- Wire Harness Assembly

- Schematic Reading and Interpretation

- Quality Control and Inspection

Work Experience

Wire Stripping Machine Operator

- Adhered to safety protocols and maintained a clean and organized work environment.

- Collaborated with production team to optimize processes and improve productivity.

- Trained new employees on wire stripping machine operation and safety procedures.

- Consistently produced high-quality wire products that met customer specifications.

Wire Stripping Machine Operator

- Set up, calibrated, and operated wire stripping machines to meet production specifications.

- Monitored machine performance and made adjustments to optimize efficiency and minimize downtime.

- Inspected finished wires for quality, ensuring compliance with standards and customer requirements.

- Troubleshooted and resolved machine malfunctions independently, reducing production delays.

Accomplishments

- Challenged the existing wire stripping process and implemented an automated solution, resulting in a 20% increase in production efficiency.

- Identified a recurring quality issue and developed a proactive inspection and maintenance routine, leading to a 15% reduction in defective products.

- Trained and supervised a team of new operators, ensuring adherence to safety procedures and optimal machine performance.

- Consistently maintained machine uptime above 95%, ensuring smooth production flow and minimizing downtime.

- Optimized wire stripping settings to achieve maximum yield while maintaining desired wire quality.

Awards

- Received the Operator of the Month award for consistently exceeding production targets and maintaining highquality standards.

- Awarded the Safety Excellence Award for adhering to all safety protocols and implementing innovative safety measures.

- Recognized with the Team Player Award for actively collaborating with colleagues and fostering a positive work environment.

Certificates

- IPC/WHMA-A-620 Wire Harness Assembly Certification

- IPC/WHMA-A-610 Cable and Wire Harness Technician Certification

- OSHA Safety Certification

- ANSI/ESD S20.20 Electrostatic Discharge Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Stripping Machine Operator

- Highlight your experience operating wire stripping machines and other related equipment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your ability to work independently and as part of a team, highlighting your communication and interpersonal skills.

- Emphasize your commitment to quality and safety, outlining your adherence to industry standards and best practices.

Essential Experience Highlights for a Strong Wire Stripping Machine Operator Resume

- Operate wire stripping machines to remove insulation from electrical wires according to specifications.

- Crimp electrical wires using hand tools or automated crimping machines to create secure connections.

- Solder and desolder wires to connect and disconnect electrical components.

- Assemble wire harnesses according to schematics and drawings, ensuring accuracy and proper routing.

- Read and interpret schematics to identify wire connections, lengths, and gauge.

- Perform quality control inspections to ensure that wire harnesses meet specifications and standards.

- Maintain a clean and organized work area, adhering to all safety protocols.

Frequently Asked Questions (FAQ’s) For Wire Stripping Machine Operator

What are the primary duties of a Wire Stripping Machine Operator?

The primary duties of a Wire Stripping Machine Operator include operating wire stripping machines to remove insulation from electrical wires, crimping electrical wires to create secure connections, soldering and desoldering wires to connect and disconnect electrical components, assembling wire harnesses according to schematics and drawings, and performing quality control inspections to ensure that wire harnesses meet specifications and standards.

What skills are required to be a successful Wire Stripping Machine Operator?

Successful Wire Stripping Machine Operators possess proficiency in operating wire stripping machines, electrical wire crimping, soldering and desoldering, wire harness assembly, schematic reading and interpretation, and quality control and inspection. They also have a strong understanding of electrical theory and principles, as well as excellent problem-solving and troubleshooting skills.

What are the career prospects for Wire Stripping Machine Operators?

Wire Stripping Machine Operators can advance their careers by gaining experience and developing additional skills. They may become supervisors or managers, or they may specialize in a particular area, such as quality control or troubleshooting. With additional education and training, they may also qualify for positions in electrical engineering or other related fields.

What is the work environment of a Wire Stripping Machine Operator like?

Wire Stripping Machine Operators typically work in manufacturing facilities. They may work in a variety of settings, including production lines, assembly areas, and test labs. The work can be repetitive and physically demanding, but it is also important and rewarding. Wire Stripping Machine Operators play a vital role in the production of electrical products, and they must be able to work independently and as part of a team.

What are the safety concerns for Wire Stripping Machine Operators?

Wire Stripping Machine Operators must be aware of the potential hazards associated with their work. These hazards include electrical shock, cuts, and eye injuries. They must follow all safety protocols and wear appropriate personal protective equipment to minimize the risk of injury.

How can I become a Wire Stripping Machine Operator?

To become a Wire Stripping Machine Operator, you typically need a high school diploma or equivalent. Some employers may require additional education or training, such as an associate degree in electrical engineering. You can also gain experience by working in a related field, such as electrical assembly or manufacturing.