Are you a seasoned Wire Weaving Loom Setter seeking a new career path? Discover our professionally built Wire Weaving Loom Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

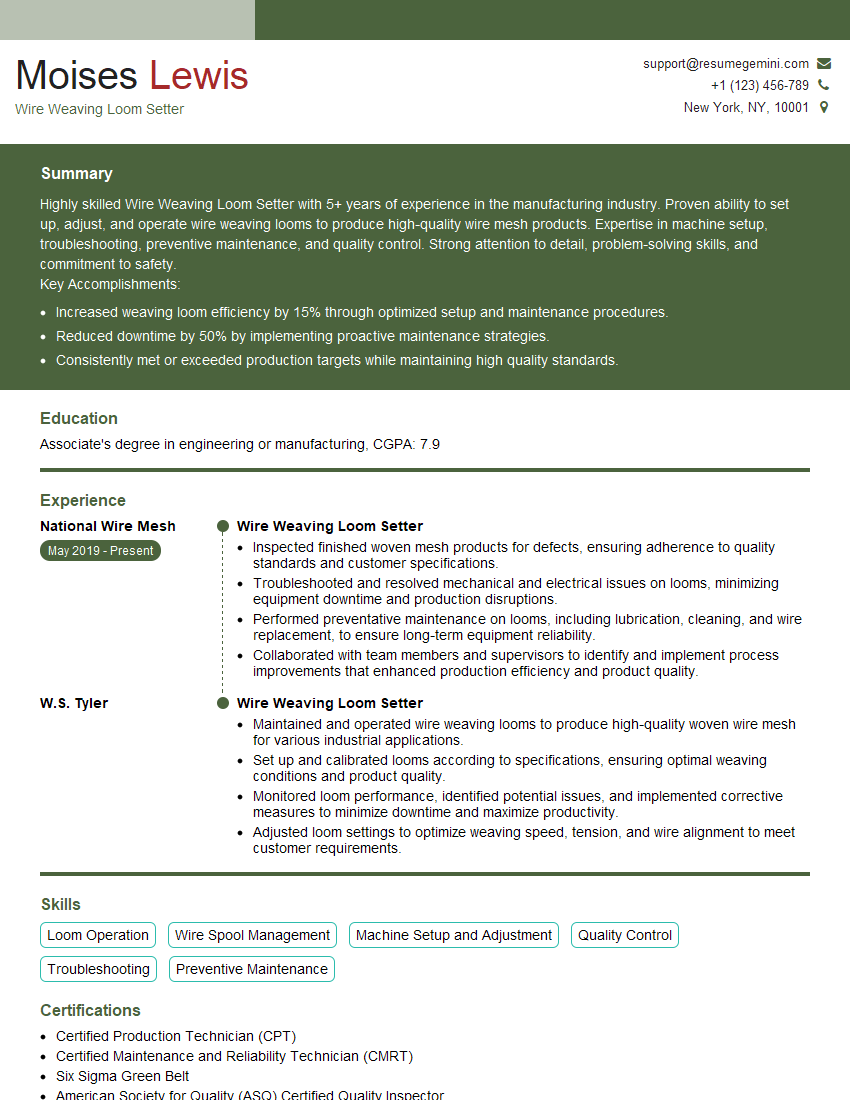

Moises Lewis

Wire Weaving Loom Setter

Summary

Highly skilled Wire Weaving Loom Setter with 5+ years of experience in the manufacturing industry. Proven ability to set up, adjust, and operate wire weaving looms to produce high-quality wire mesh products. Expertise in machine setup, troubleshooting, preventive maintenance, and quality control. Strong attention to detail, problem-solving skills, and commitment to safety.

Key Accomplishments:

- Increased weaving loom efficiency by 15% through optimized setup and maintenance procedures.

- Reduced downtime by 50% by implementing proactive maintenance strategies.

- Consistently met or exceeded production targets while maintaining high quality standards.

Education

Associate’s degree in engineering or manufacturing

April 2015

Skills

- Loom Operation

- Wire Spool Management

- Machine Setup and Adjustment

- Quality Control

- Troubleshooting

- Preventive Maintenance

Work Experience

Wire Weaving Loom Setter

- Inspected finished woven mesh products for defects, ensuring adherence to quality standards and customer specifications.

- Troubleshooted and resolved mechanical and electrical issues on looms, minimizing equipment downtime and production disruptions.

- Performed preventative maintenance on looms, including lubrication, cleaning, and wire replacement, to ensure long-term equipment reliability.

- Collaborated with team members and supervisors to identify and implement process improvements that enhanced production efficiency and product quality.

Wire Weaving Loom Setter

- Maintained and operated wire weaving looms to produce high-quality woven wire mesh for various industrial applications.

- Set up and calibrated looms according to specifications, ensuring optimal weaving conditions and product quality.

- Monitored loom performance, identified potential issues, and implemented corrective measures to minimize downtime and maximize productivity.

- Adjusted loom settings to optimize weaving speed, tension, and wire alignment to meet customer requirements.

Certificates

- Certified Production Technician (CPT)

- Certified Maintenance and Reliability Technician (CMRT)

- Six Sigma Green Belt

- American Society for Quality (ASQ) Certified Quality Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Weaving Loom Setter

Highlight Your Experience and Skills:

Quantify your accomplishments and use specific examples to demonstrate your expertise in loom operation, machine setup, and troubleshooting.

Showcase Your Problem-Solving Abilities:

Emphasize your ability to diagnose and resolve loom issues efficiently, minimizing downtime and maintaining productivity.

Demonstrate Your Commitment to Quality:

Highlight your attention to detail and your commitment to producing high-quality wire mesh products that meet or exceed customer specifications.

Emphasize Your Safety Awareness:

State your adherence to safety regulations and your commitment to maintaining a safe and organized work environment.

Essential Experience Highlights for a Strong Wire Weaving Loom Setter Resume

- Set up, adjust, and operate wire weaving looms according to specifications.

- Manage wire spool inventory and ensure smooth flow of materials.

- Troubleshoot and resolve loom malfunctions to minimize downtime.

- Conduct routine preventive maintenance to keep looms in optimal condition.

- Monitor product quality and make adjustments as needed to meet specifications.

- Adhere to safety regulations and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Wire Weaving Loom Setter

What is the role of a Wire Weaving Loom Setter?

A Wire Weaving Loom Setter is responsible for setting up, maintaining, and operating wire weaving looms to produce wire mesh products. They ensure that the looms are operating efficiently, troubleshoot and resolve issues, and maintain the quality of the finished product.

What skills are required for this role?

Essential skills include loom operation, wire spool management, machine setup and adjustment, troubleshooting, preventive maintenance, and quality control.

What education is required to become a Wire Weaving Loom Setter?

An associate’s degree in engineering or manufacturing is often preferred, but some employers may accept relevant work experience in lieu of a degree.

What is the average salary for a Wire Weaving Loom Setter?

The average salary for a Wire Weaving Loom Setter in the United States is around $25,000 to $45,000 per year.

What are the career advancement opportunities for this role?

With experience and additional training, Wire Weaving Loom Setters can advance to roles such as Loom Supervisor, Manufacturing Technician, or Quality Control Inspector.

Is this role physically demanding?

Yes, this role involves lifting heavy materials, standing for long periods, and operating machinery, making it physically demanding.

What industries employ Wire Weaving Loom Setters??

Wire Weaving Loom Setters are employed in various industries that use wire mesh products, such as mining, food processing, and construction.