Are you a seasoned Wood Pattern Maker seeking a new career path? Discover our professionally built Wood Pattern Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

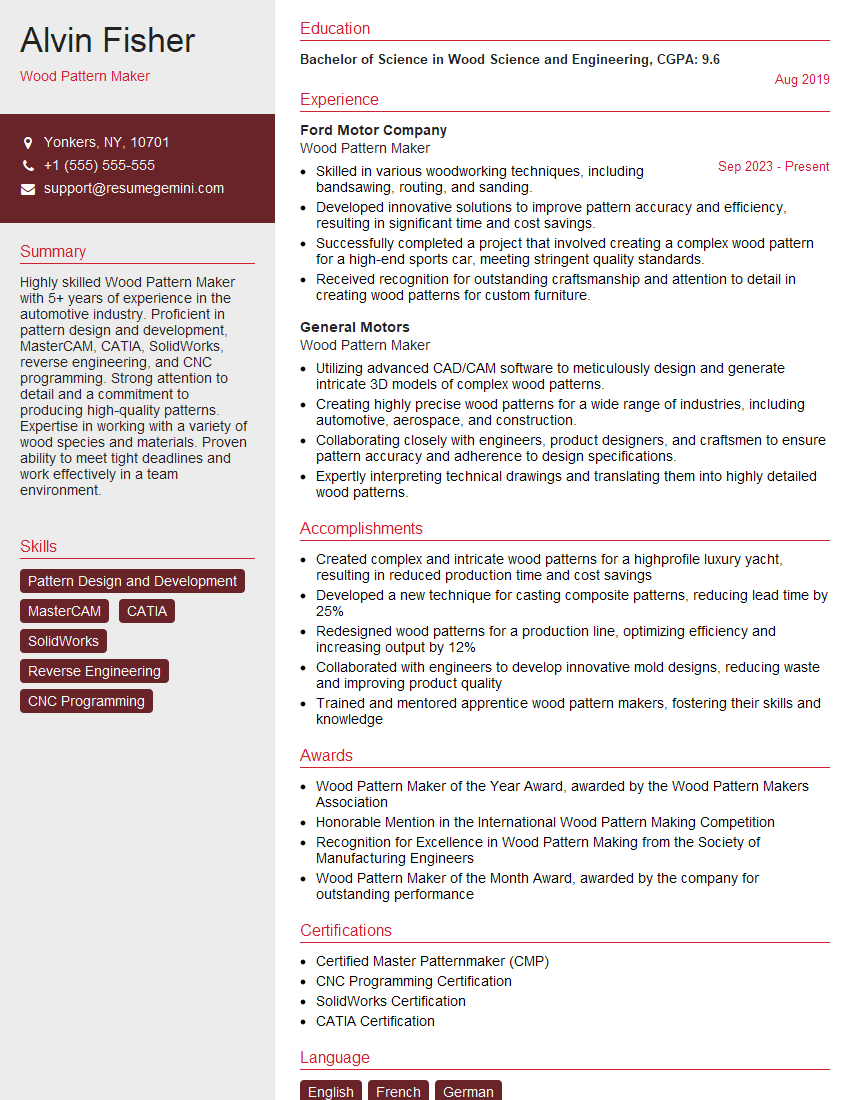

Alvin Fisher

Wood Pattern Maker

Summary

Highly skilled Wood Pattern Maker with 5+ years of experience in the automotive industry. Proficient in pattern design and development, MasterCAM, CATIA, SolidWorks, reverse engineering, and CNC programming. Strong attention to detail and a commitment to producing high-quality patterns. Expertise in working with a variety of wood species and materials. Proven ability to meet tight deadlines and work effectively in a team environment.

Education

Bachelor of Science in Wood Science and Engineering

August 2019

Skills

- Pattern Design and Development

- MasterCAM

- CATIA

- SolidWorks

- Reverse Engineering

- CNC Programming

Work Experience

Wood Pattern Maker

- Skilled in various woodworking techniques, including bandsawing, routing, and sanding.

- Developed innovative solutions to improve pattern accuracy and efficiency, resulting in significant time and cost savings.

- Successfully completed a project that involved creating a complex wood pattern for a high-end sports car, meeting stringent quality standards.

- Received recognition for outstanding craftsmanship and attention to detail in creating wood patterns for custom furniture.

Wood Pattern Maker

- Utilizing advanced CAD/CAM software to meticulously design and generate intricate 3D models of complex wood patterns.

- Creating highly precise wood patterns for a wide range of industries, including automotive, aerospace, and construction.

- Collaborating closely with engineers, product designers, and craftsmen to ensure pattern accuracy and adherence to design specifications.

- Expertly interpreting technical drawings and translating them into highly detailed wood patterns.

Accomplishments

- Created complex and intricate wood patterns for a highprofile luxury yacht, resulting in reduced production time and cost savings

- Developed a new technique for casting composite patterns, reducing lead time by 25%

- Redesigned wood patterns for a production line, optimizing efficiency and increasing output by 12%

- Collaborated with engineers to develop innovative mold designs, reducing waste and improving product quality

- Trained and mentored apprentice wood pattern makers, fostering their skills and knowledge

Awards

- Wood Pattern Maker of the Year Award, awarded by the Wood Pattern Makers Association

- Honorable Mention in the International Wood Pattern Making Competition

- Recognition for Excellence in Wood Pattern Making from the Society of Manufacturing Engineers

- Wood Pattern Maker of the Month Award, awarded by the company for outstanding performance

Certificates

- Certified Master Patternmaker (CMP)

- CNC Programming Certification

- SolidWorks Certification

- CATIA Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wood Pattern Maker

- Highlight your skills and experience in pattern design and development, using specific examples from your previous work.

- Showcase your proficiency in CAD software and CNC programming, providing examples of projects you have completed using these tools.

- Demonstrate your understanding of the casting process and how wood patterns are used in it.

- Emphasize your attention to detail and commitment to producing high-quality work.

Essential Experience Highlights for a Strong Wood Pattern Maker Resume

- Design and develop wood patterns for automotive components using CAD software such as MasterCAM, CATIA, and SolidWorks.

- Perform reverse engineering on existing components to create digital patterns.

- Program CNC machines to cut and shape patterns according to design specifications.

- Inspect patterns for quality and accuracy before they are used in the casting process.

- Troubleshoot and resolve issues that arise during the pattern-making process.

- Maintain a clean and organized work area.

- Stay up-to-date on the latest industry trends and technologies related to pattern-making.

Frequently Asked Questions (FAQ’s) For Wood Pattern Maker

What is the role of a Wood Pattern Maker?

A Wood Pattern Maker is responsible for designing, developing, and creating wooden patterns used in the casting process. These patterns are used to create molds for casting metal components, such as those used in the automotive industry.

What skills are required to be a Wood Pattern Maker?

Wood Pattern Makers typically need a strong understanding of pattern design and development, as well as proficiency in CAD software and CNC programming. They also need to have a good understanding of the casting process and the properties of different wood species.

What is the career outlook for Wood Pattern Makers?

The career outlook for Wood Pattern Makers is expected to be good over the next few years. The automotive industry is expected to continue to grow, which will lead to an increased demand for skilled Wood Pattern Makers.

What is the average salary for Wood Pattern Makers?

The average salary for Wood Pattern Makers is around $60,000 per year.

What are the different types of wood patterns that Wood Pattern Makers create?

Wood Pattern Makers create a variety of different types of wood patterns, including patterns for castings, molds, and jigs. They also create patterns for architectural elements, such as decorative moldings and trim.

What are the different materials that Wood Pattern Makers use?

Wood Pattern Makers use a variety of different materials, including wood, plastic, and metal. They also use a variety of different tools and equipment, including CAD software, CNC machines, and woodworking tools.