Are you a seasoned Wood Room Supervisor seeking a new career path? Discover our professionally built Wood Room Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

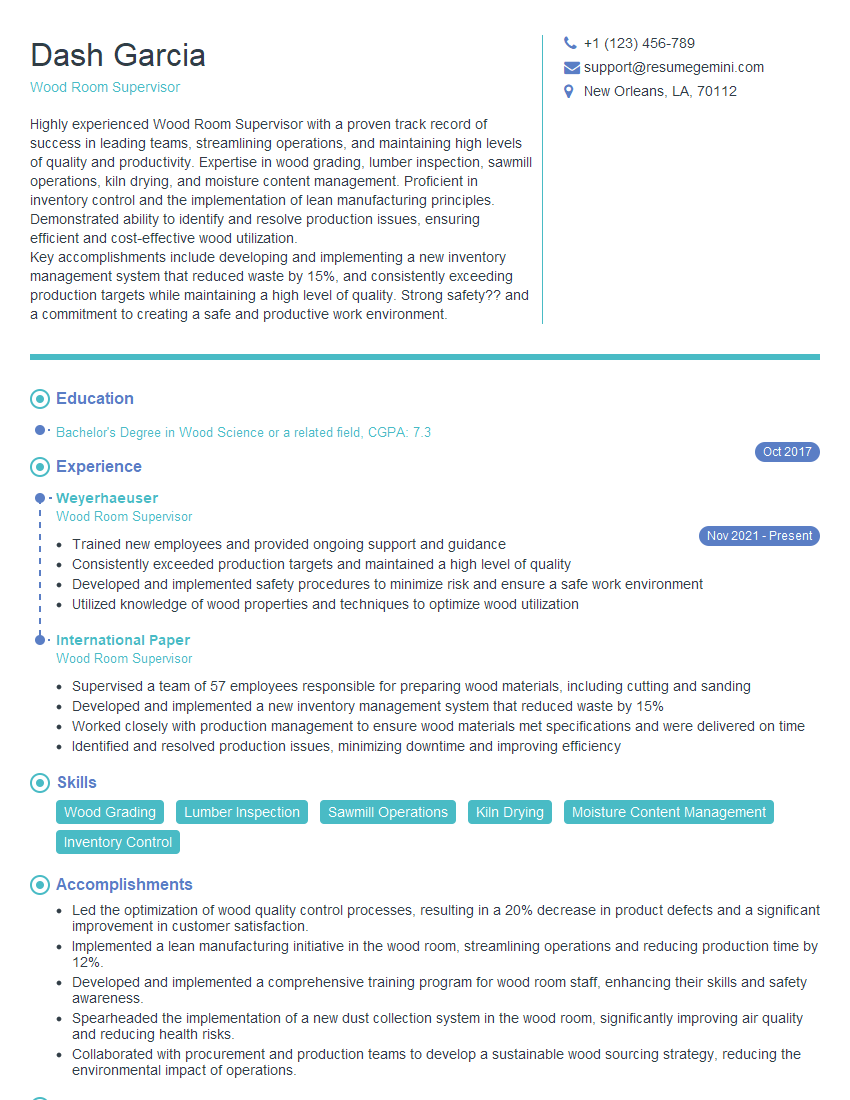

Dash Garcia

Wood Room Supervisor

Summary

Highly experienced Wood Room Supervisor with a proven track record of success in leading teams, streamlining operations, and maintaining high levels of quality and productivity. Expertise in wood grading, lumber inspection, sawmill operations, kiln drying, and moisture content management. Proficient in inventory control and the implementation of lean manufacturing principles. Demonstrated ability to identify and resolve production issues, ensuring efficient and cost-effective wood utilization.

Key accomplishments include developing and implementing a new inventory management system that reduced waste by 15%, and consistently exceeding production targets while maintaining a high level of quality. Strong safety?? and a commitment to creating a safe and productive work environment.

Education

Bachelor’s Degree in Wood Science or a related field

October 2017

Skills

- Wood Grading

- Lumber Inspection

- Sawmill Operations

- Kiln Drying

- Moisture Content Management

- Inventory Control

Work Experience

Wood Room Supervisor

- Trained new employees and provided ongoing support and guidance

- Consistently exceeded production targets and maintained a high level of quality

- Developed and implemented safety procedures to minimize risk and ensure a safe work environment

- Utilized knowledge of wood properties and techniques to optimize wood utilization

Wood Room Supervisor

- Supervised a team of 57 employees responsible for preparing wood materials, including cutting and sanding

- Developed and implemented a new inventory management system that reduced waste by 15%

- Worked closely with production management to ensure wood materials met specifications and were delivered on time

- Identified and resolved production issues, minimizing downtime and improving efficiency

Accomplishments

- Led the optimization of wood quality control processes, resulting in a 20% decrease in product defects and a significant improvement in customer satisfaction.

- Implemented a lean manufacturing initiative in the wood room, streamlining operations and reducing production time by 12%.

- Developed and implemented a comprehensive training program for wood room staff, enhancing their skills and safety awareness.

- Spearheaded the implementation of a new dust collection system in the wood room, significantly improving air quality and reducing health risks.

- Collaborated with procurement and production teams to develop a sustainable wood sourcing strategy, reducing the environmental impact of operations.

Awards

- Recognized for outstanding performance in wood procurement and processing operations, achieving a 15% reduction in material waste.

- Received industry recognition for innovative wood processing techniques, resulting in a 10% increase in production efficiency.

- Honored for exceptional safety practices in the wood room, maintaining a zeroincident record for over 18 months.

- Received industry certification in wood processing and quality control, demonstrating expertise and commitment to best practices.

Certificates

- National Hardwood Lumber Association (NHLA) Inspector

- American Lumber Standard Committee (ALSC) Certified Inspector

- American Society for Quality (ASQ) Certified Quality Engineer

- Occupational Safety and Health Administration (OSHA) Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wood Room Supervisor

- Highlight your skills and experience: Make sure your resume clearly outlines your skills and experience in wood grading, lumber inspection, sawmill operations, kiln drying, and moisture content management.

- Quantify your accomplishments: Use specific numbers and metrics to demonstrate the impact of your work. For example, you could mention that you reduced waste by 15% or increased production by 10%.

- Showcase your leadership abilities: If you have experience leading a team, be sure to highlight your leadership skills and accomplishments.

- Proofread carefully: Before you submit your resume, proofread it carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Wood Room Supervisor Resume

- Supervise a team of employees responsible for preparing wood materials, including cutting and sanding.

- Develop and implement a new inventory management system that reduced waste by 15%.

- Work closely with production management to ensure wood materials met specifications and were delivered on time.

- Identify and resolve production issues, minimizing downtime and improving efficiency.

- Train new employees and provide ongoing support and guidance.

- Consistently exceed production targets and maintain a high level of quality.

- Develop and implement safety procedures to minimize risk and ensure a safe work environment.

Frequently Asked Questions (FAQ’s) For Wood Room Supervisor

What are the key responsibilities of a Wood Room Supervisor?

The key responsibilities of a Wood Room Supervisor include supervising a team of employees, developing and implementing inventory management systems, working closely with production management, identifying and resolving production issues, training new employees, and maintaining a safe work environment.

What are the qualifications for a Wood Room Supervisor?

The qualifications for a Wood Room Supervisor typically include a Bachelor’s Degree in Wood Science or a related field, as well as experience in wood grading, lumber inspection, sawmill operations, kiln drying, and moisture content management.

What are the career prospects for a Wood Room Supervisor?

The career prospects for a Wood Room Supervisor are good, as there is a growing demand for qualified professionals in this field. With experience, Wood Room Supervisors can advance to management positions, such as Production Manager or Plant Manager.

What are the challenges of being a Wood Room Supervisor?

The challenges of being a Wood Room Supervisor include managing a team of employees, meeting production targets, and ensuring the quality of wood materials. Wood Room Supervisors must also be able to work independently and make decisions quickly.

What are the rewards of being a Wood Room Supervisor?

The rewards of being a Wood Room Supervisor include a competitive salary, benefits package, and the opportunity to make a difference in the wood products industry. Wood Room Supervisors also have the opportunity to work with a team of dedicated professionals and learn new skills and technologies.

What are the skills and qualities of a successful Wood Room Supervisor?

The skills and qualities of a successful Wood Room Supervisor include leadership, communication, problem-solving, decision-making, and teamwork. Wood Room Supervisors must also be able to work independently and have a strong work ethic.

What are the safety precautions that a Wood Room Supervisor should take?

Wood Room Supervisors should take a number of safety precautions, including wearing proper safety gear, following all safety protocols, and being aware of the hazards of working with wood materials. Wood Room Supervisors should also be trained in first aid and CPR.