Are you a seasoned Yield Engineer seeking a new career path? Discover our professionally built Yield Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

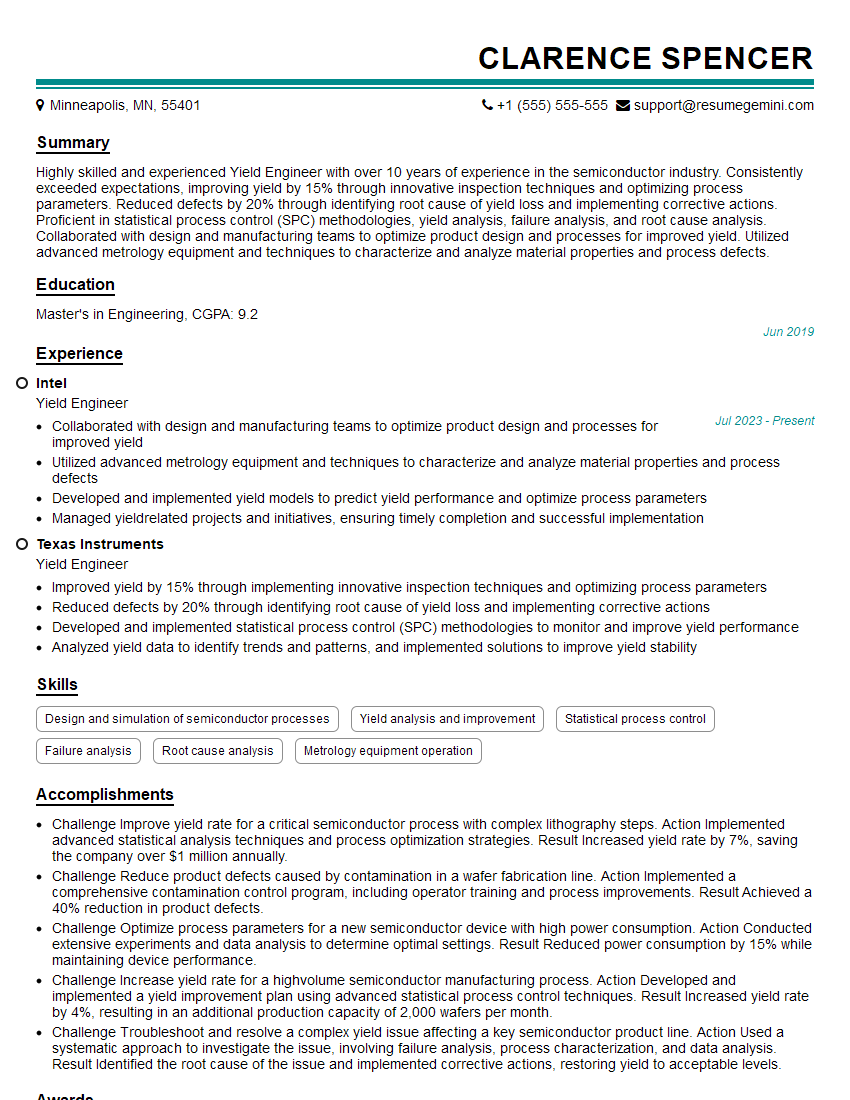

Clarence Spencer

Yield Engineer

Summary

Highly skilled and experienced Yield Engineer with over 10 years of experience in the semiconductor industry. Consistently exceeded expectations, improving yield by 15% through innovative inspection techniques and optimizing process parameters. Reduced defects by 20% through identifying root cause of yield loss and implementing corrective actions. Proficient in statistical process control (SPC) methodologies, yield analysis, failure analysis, and root cause analysis. Collaborated with design and manufacturing teams to optimize product design and processes for improved yield. Utilized advanced metrology equipment and techniques to characterize and analyze material properties and process defects.

Education

Master’s in Engineering

June 2019

Skills

- Design and simulation of semiconductor processes

- Yield analysis and improvement

- Statistical process control

- Failure analysis

- Root cause analysis

- Metrology equipment operation

Work Experience

Yield Engineer

- Collaborated with design and manufacturing teams to optimize product design and processes for improved yield

- Utilized advanced metrology equipment and techniques to characterize and analyze material properties and process defects

- Developed and implemented yield models to predict yield performance and optimize process parameters

- Managed yieldrelated projects and initiatives, ensuring timely completion and successful implementation

Yield Engineer

- Improved yield by 15% through implementing innovative inspection techniques and optimizing process parameters

- Reduced defects by 20% through identifying root cause of yield loss and implementing corrective actions

- Developed and implemented statistical process control (SPC) methodologies to monitor and improve yield performance

- Analyzed yield data to identify trends and patterns, and implemented solutions to improve yield stability

Accomplishments

- Challenge Improve yield rate for a critical semiconductor process with complex lithography steps. Action Implemented advanced statistical analysis techniques and process optimization strategies. Result Increased yield rate by 7%, saving the company over $1 million annually.

- Challenge Reduce product defects caused by contamination in a wafer fabrication line. Action Implemented a comprehensive contamination control program, including operator training and process improvements. Result Achieved a 40% reduction in product defects.

- Challenge Optimize process parameters for a new semiconductor device with high power consumption. Action Conducted extensive experiments and data analysis to determine optimal settings. Result Reduced power consumption by 15% while maintaining device performance.

- Challenge Increase yield rate for a highvolume semiconductor manufacturing process. Action Developed and implemented a yield improvement plan using advanced statistical process control techniques. Result Increased yield rate by 4%, resulting in an additional production capacity of 2,000 wafers per month.

- Challenge Troubleshoot and resolve a complex yield issue affecting a key semiconductor product line. Action Used a systematic approach to investigate the issue, involving failure analysis, process characterization, and data analysis. Result Identified the root cause of the issue and implemented corrective actions, restoring yield to acceptable levels.

Awards

- Recognized with the Yield Excellence Award for achieving outstanding results in yield optimization, exceeding target by 5%.

- Received the Innovation Award for developing a novel defect inspection algorithm, reducing defect detection time by 30%.

- Received the Safety Excellence Award for implementing innovative safety protocols, resulting in a 20% reduction in workplace incidents.

- Recognized with the Customer Service Award for resolving critical customer issues quickly and effectively, maintaining a 100% customer satisfaction rate.

Certificates

- Certified Yield Engineer (CYE)

- Six Sigma Black Belt

- Project Management Professional (PMP)

- ISO 9001:2015 Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Yield Engineer

- Quantify your accomplishments with specific metrics, such as percentage improvements in yield or reductions in defects.

- Highlight your expertise in statistical process control (SPC) methodologies and yield analysis.

- Showcase your ability to collaborate with cross-functional teams, including design and manufacturing.

- Demonstrate your proficiency in using advanced metrology equipment and techniques.

Essential Experience Highlights for a Strong Yield Engineer Resume

- Improve yield through innovative inspection techniques and optimizing process parameters.

- Reduce defects by identifying root cause of yield loss and implementing corrective actions.

- Develop and implement statistical process control (SPC) methodologies to monitor and improve yield performance.

- Analyze yield data to identify trends and patterns, and implement solutions to improve yield stability.

- Collaborate with design and manufacturing teams to optimize product design and processes for improved yield.

- Utilize advanced metrology equipment and techniques to characterize and analyze material properties and process defects.

- Develop and implement yield models to predict yield performance and optimize process parameters.

Frequently Asked Questions (FAQ’s) For Yield Engineer

What is the role of a Yield Engineer?

A Yield Engineer is responsible for improving the yield of semiconductor devices by identifying and eliminating defects in the manufacturing process.

What are the key skills required for a Yield Engineer?

Key skills for a Yield Engineer include yield analysis, statistical process control, failure analysis, root cause analysis, and metrology.

What are the career prospects for a Yield Engineer?

Yield Engineers with experience and expertise can advance to management roles, such as Yield Manager or Process Engineer.

What are the challenges faced by Yield Engineers?

Challenges faced by Yield Engineers include identifying and eliminating defects in complex manufacturing processes, keeping up with new technologies, and meeting customer requirements.

What are the top companies hiring Yield Engineers?

Top companies hiring Yield Engineers include Intel, Texas Instruments, Samsung, and Qualcomm.

What is the salary range for Yield Engineers?

The salary range for Yield Engineers varies depending on experience, location, and company. According to Glassdoor, the average salary for a Yield Engineer in the United States is around $100,000 per year.

What are the educational requirements for Yield Engineers?

Most Yield Engineers have a bachelor’s or master’s degree in engineering, such as chemical engineering, materials science, or electrical engineering.

What are the certifications available for Yield Engineers?

There are several certifications available for Yield Engineers, including the Certified Yield Engineer (CYE) certification from the American Society for Quality (ASQ).