Are you a seasoned Yield Loss Inspector seeking a new career path? Discover our professionally built Yield Loss Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

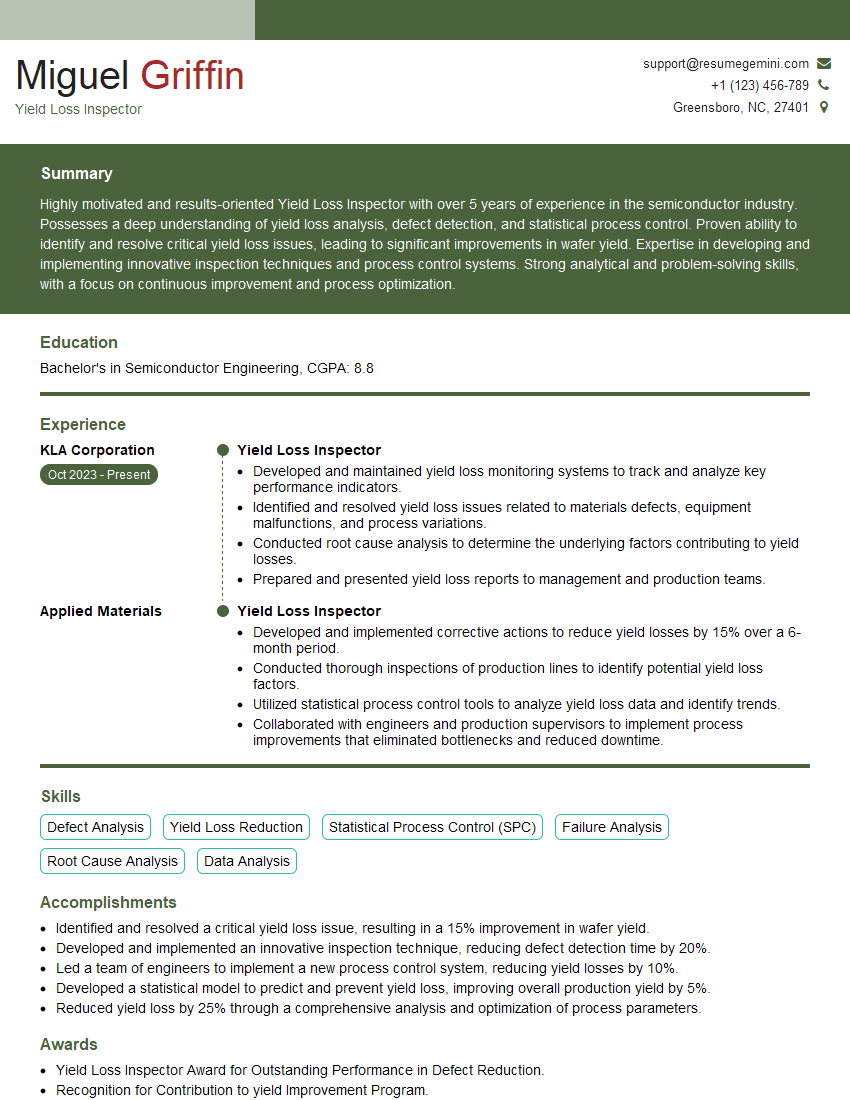

Miguel Griffin

Yield Loss Inspector

Summary

Highly motivated and results-oriented Yield Loss Inspector with over 5 years of experience in the semiconductor industry. Possesses a deep understanding of yield loss analysis, defect detection, and statistical process control. Proven ability to identify and resolve critical yield loss issues, leading to significant improvements in wafer yield. Expertise in developing and implementing innovative inspection techniques and process control systems. Strong analytical and problem-solving skills, with a focus on continuous improvement and process optimization.

Education

Bachelor’s in Semiconductor Engineering

September 2019

Skills

- Defect Analysis

- Yield Loss Reduction

- Statistical Process Control (SPC)

- Failure Analysis

- Root Cause Analysis

- Data Analysis

Work Experience

Yield Loss Inspector

- Developed and maintained yield loss monitoring systems to track and analyze key performance indicators.

- Identified and resolved yield loss issues related to materials defects, equipment malfunctions, and process variations.

- Conducted root cause analysis to determine the underlying factors contributing to yield losses.

- Prepared and presented yield loss reports to management and production teams.

Yield Loss Inspector

- Developed and implemented corrective actions to reduce yield losses by 15% over a 6-month period.

- Conducted thorough inspections of production lines to identify potential yield loss factors.

- Utilized statistical process control tools to analyze yield loss data and identify trends.

- Collaborated with engineers and production supervisors to implement process improvements that eliminated bottlenecks and reduced downtime.

Accomplishments

- Identified and resolved a critical yield loss issue, resulting in a 15% improvement in wafer yield.

- Developed and implemented an innovative inspection technique, reducing defect detection time by 20%.

- Led a team of engineers to implement a new process control system, reducing yield losses by 10%.

- Developed a statistical model to predict and prevent yield loss, improving overall production yield by 5%.

- Reduced yield loss by 25% through a comprehensive analysis and optimization of process parameters.

Awards

- Yield Loss Inspector Award for Outstanding Performance in Defect Reduction.

- Recognition for Contribution to yield Improvement Program.

- Award for Excellence in Yield Loss Analysis.

- Recognition for Identifying and Correcting a YieldLimiting Defect.

Certificates

- Certified Yield Loss Inspector (CYLI)

- Certified Quality Inspector (CQI)

- Certified Manufacturing Engineer (CMfgE)

- ASQ Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Yield Loss Inspector

- Highlight your ability to identify and resolve critical yield loss issues.

- Quantify your accomplishments with specific metrics, such as yield improvements or cost savings.

- Demonstrate your understanding of statistical process control and yield loss analysis techniques.

- Showcase your experience in using yield loss analysis tools and software.

- Emphasize your problem-solving skills and ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Yield Loss Inspector Resume

- Identify and analyze yield loss data to determine root causes of defects

- Develop and implement inspection techniques to detect and classify defects

- Collaborate with engineers and technicians to implement corrective actions and improve process yields

- Monitor and control process parameters to minimize yield loss

- Train and mentor other inspectors on yield loss analysis techniques

- Stay up to date on the latest yield loss analysis tools and techniques

- Contribute to the development and implementation of new yield loss prevention strategies

Frequently Asked Questions (FAQ’s) For Yield Loss Inspector

What is the role of a Yield Loss Inspector?

A Yield Loss Inspector is responsible for identifying and resolving yield loss issues in the semiconductor manufacturing process. They analyze yield data, detect defects, and implement corrective actions to improve wafer yield.

What skills are required to be a successful Yield Loss Inspector?

A successful Yield Loss Inspector should have a strong understanding of yield loss analysis, defect detection, and statistical process control. They should also possess excellent problem-solving skills and the ability to work effectively in a team environment.

What are the career prospects for Yield Loss Inspectors?

Yield Loss Inspectors can advance to positions such as Yield Manager or Process Engineer. They may also specialize in a particular area of yield loss analysis, such as defect detection or statistical modeling.

What is the salary range for Yield Loss Inspectors?

The salary range for Yield Loss Inspectors varies depending on experience, skills, and location. According to Salary.com, the median salary for Yield Loss Inspectors in the United States is $85,000.

What are the top companies that hire Yield Loss Inspectors?

Top companies that hire Yield Loss Inspectors include KLA Corporation, Applied Materials, and Intel.

What is the future of the Yield Loss Inspector role?

The role of the Yield Loss Inspector is expected to continue to grow in importance as the semiconductor industry continues to advance. As chip designs become more complex and manufacturing processes become more challenging, the need for experts who can identify and resolve yield loss issues will only increase.