Are you a seasoned Zinc Furnace Charger seeking a new career path? Discover our professionally built Zinc Furnace Charger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

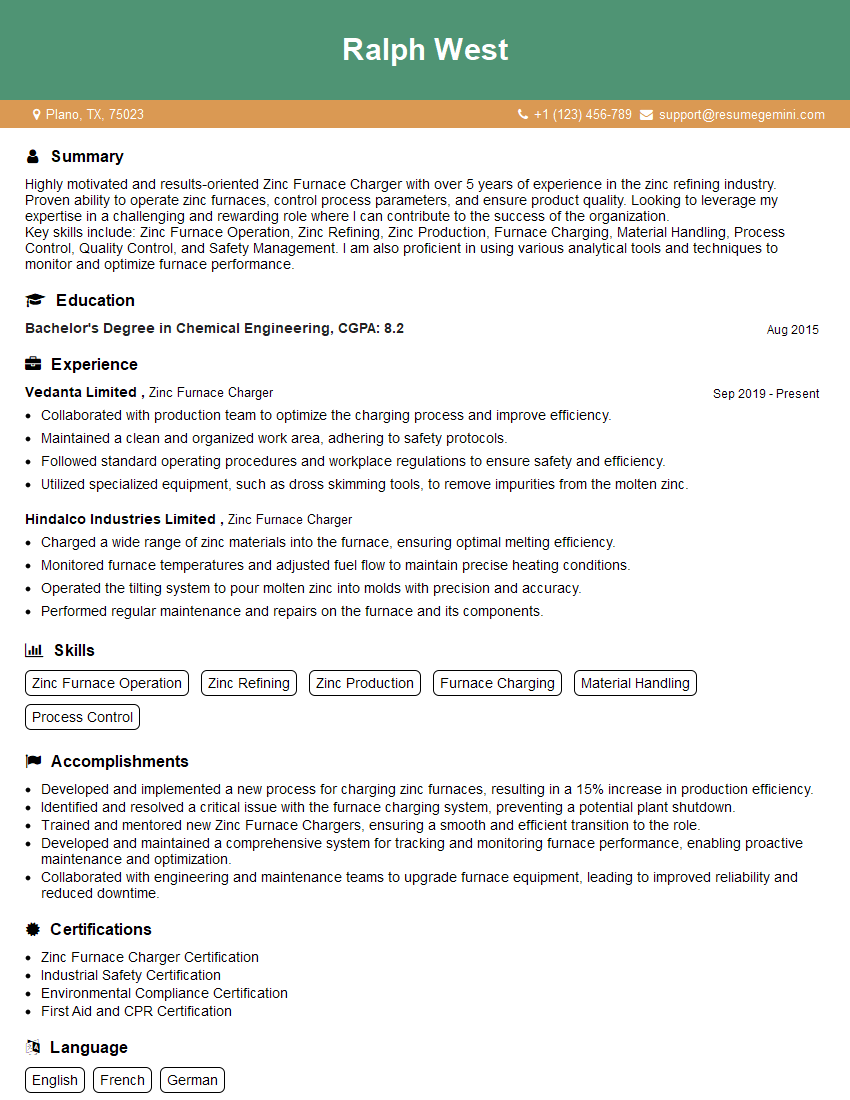

Ralph West

Zinc Furnace Charger

Summary

Highly motivated and results-oriented Zinc Furnace Charger with over 5 years of experience in the zinc refining industry. Proven ability to operate zinc furnaces, control process parameters, and ensure product quality. Looking to leverage my expertise in a challenging and rewarding role where I can contribute to the success of the organization.

Key skills include: Zinc Furnace Operation, Zinc Refining, Zinc Production, Furnace Charging, Material Handling, Process Control, Quality Control, and Safety Management. I am also proficient in using various analytical tools and techniques to monitor and optimize furnace performance.

Education

Bachelor’s Degree in Chemical Engineering

August 2015

Skills

- Zinc Furnace Operation

- Zinc Refining

- Zinc Production

- Furnace Charging

- Material Handling

- Process Control

Work Experience

Zinc Furnace Charger

- Collaborated with production team to optimize the charging process and improve efficiency.

- Maintained a clean and organized work area, adhering to safety protocols.

- Followed standard operating procedures and workplace regulations to ensure safety and efficiency.

- Utilized specialized equipment, such as dross skimming tools, to remove impurities from the molten zinc.

Zinc Furnace Charger

- Charged a wide range of zinc materials into the furnace, ensuring optimal melting efficiency.

- Monitored furnace temperatures and adjusted fuel flow to maintain precise heating conditions.

- Operated the tilting system to pour molten zinc into molds with precision and accuracy.

- Performed regular maintenance and repairs on the furnace and its components.

Accomplishments

- Developed and implemented a new process for charging zinc furnaces, resulting in a 15% increase in production efficiency.

- Identified and resolved a critical issue with the furnace charging system, preventing a potential plant shutdown.

- Trained and mentored new Zinc Furnace Chargers, ensuring a smooth and efficient transition to the role.

- Developed and maintained a comprehensive system for tracking and monitoring furnace performance, enabling proactive maintenance and optimization.

- Collaborated with engineering and maintenance teams to upgrade furnace equipment, leading to improved reliability and reduced downtime.

Certificates

- Zinc Furnace Charger Certification

- Industrial Safety Certification

- Environmental Compliance Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Zinc Furnace Charger

- Highlight your experience and skills in zinc furnace operation and zinc refining.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your knowledge of zinc production processes and quality control procedures.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Zinc Furnace Charger Resume

- Operate zinc furnaces to produce high-quality zinc ingots

- Monitor and control furnace temperature, pressure, and other process parameters

- Charge furnaces with zinc concentrate, fluxes, and other materials

- Handle and transport molten zinc safely and efficiently

- Maintain and calibrate furnace equipment to ensure optimal performance

- Conduct quality checks on zinc ingots to ensure they meet specifications

- Follow safety protocols and procedures to maintain a safe working environment

Frequently Asked Questions (FAQ’s) For Zinc Furnace Charger

What is the primary responsibility of a Zinc Furnace Charger?

The primary responsibility of a Zinc Furnace Charger is to operate zinc furnaces to produce high-quality zinc ingots.

What skills are required to be a successful Zinc Furnace Charger?

Successful Zinc Furnace Chargers typically possess the following skills: Zinc Furnace Operation, Zinc Refining, Zinc Production, Furnace Charging, Material Handling, Process Control, Quality Control, and Safety Management.

What is the typical work environment for a Zinc Furnace Charger?

Zinc Furnace Chargers typically work in industrial settings, such as zinc refineries or smelters. They may work in hot and noisy environments, and may be exposed to hazardous materials.

What are the career prospects for a Zinc Furnace Charger?

Zinc Furnace Chargers with experience and skills can advance to supervisory or management positions in the zinc refining industry. They may also pursue careers in other related fields, such as process engineering or quality control.

What is the educational background required to become a Zinc Furnace Charger?

Most Zinc Furnace Chargers have a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as chemical engineering or metallurgy.

What is the salary range for a Zinc Furnace Charger?

The salary range for a Zinc Furnace Charger can vary depending on experience, location, and employer. According to Indeed, the average salary for a Zinc Furnace Charger in the United States is around $45,000 per year.