Are you a seasoned Zinc Plate Cutter seeking a new career path? Discover our professionally built Zinc Plate Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

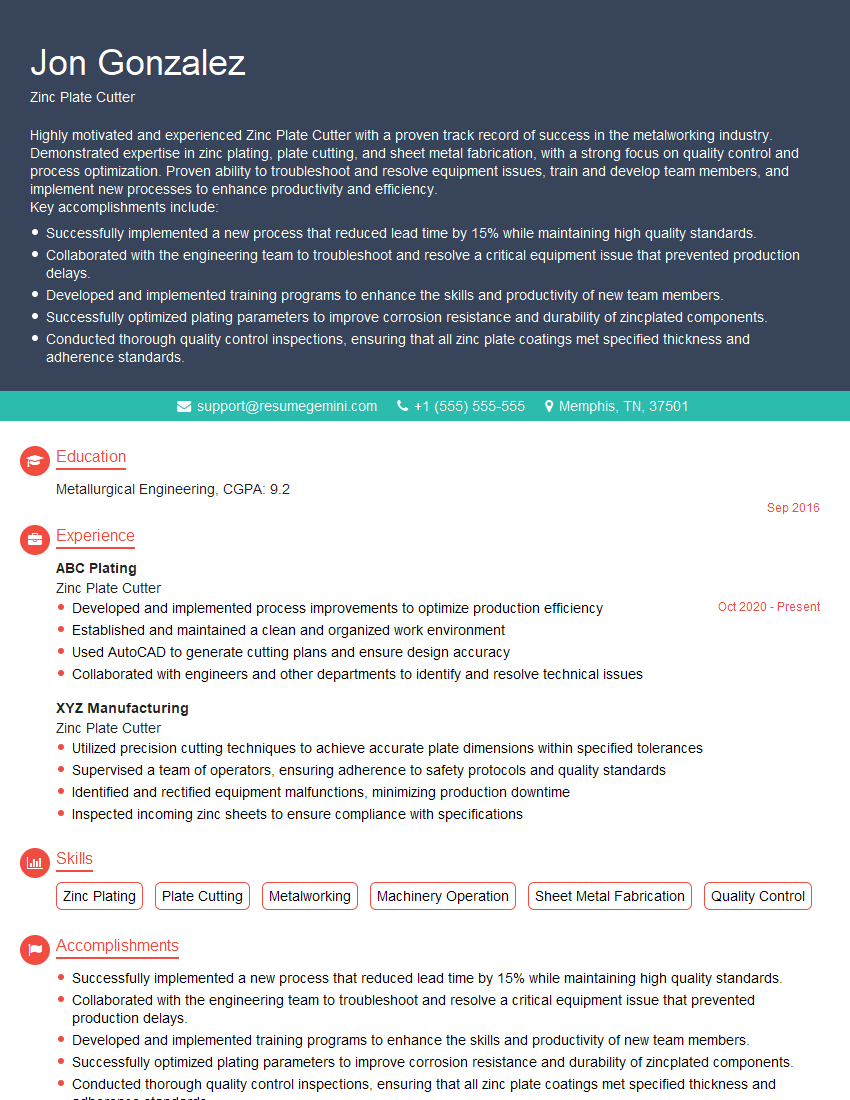

Jon Gonzalez

Zinc Plate Cutter

Summary

Highly motivated and experienced Zinc Plate Cutter with a proven track record of success in the metalworking industry. Demonstrated expertise in zinc plating, plate cutting, and sheet metal fabrication, with a strong focus on quality control and process optimization. Proven ability to troubleshoot and resolve equipment issues, train and develop team members, and implement new processes to enhance productivity and efficiency.

Key accomplishments include:

- Successfully implemented a new process that reduced lead time by 15% while maintaining high quality standards.

- Collaborated with the engineering team to troubleshoot and resolve a critical equipment issue that prevented production delays.

- Developed and implemented training programs to enhance the skills and productivity of new team members.

- Successfully optimized plating parameters to improve corrosion resistance and durability of zincplated components.

- Conducted thorough quality control inspections, ensuring that all zinc plate coatings met specified thickness and adherence standards.

Education

Metallurgical Engineering

September 2016

Skills

- Zinc Plating

- Plate Cutting

- Metalworking

- Machinery Operation

- Sheet Metal Fabrication

- Quality Control

Work Experience

Zinc Plate Cutter

- Developed and implemented process improvements to optimize production efficiency

- Established and maintained a clean and organized work environment

- Used AutoCAD to generate cutting plans and ensure design accuracy

- Collaborated with engineers and other departments to identify and resolve technical issues

Zinc Plate Cutter

- Utilized precision cutting techniques to achieve accurate plate dimensions within specified tolerances

- Supervised a team of operators, ensuring adherence to safety protocols and quality standards

- Identified and rectified equipment malfunctions, minimizing production downtime

- Inspected incoming zinc sheets to ensure compliance with specifications

Accomplishments

- Successfully implemented a new process that reduced lead time by 15% while maintaining high quality standards.

- Collaborated with the engineering team to troubleshoot and resolve a critical equipment issue that prevented production delays.

- Developed and implemented training programs to enhance the skills and productivity of new team members.

- Successfully optimized plating parameters to improve corrosion resistance and durability of zincplated components.

- Conducted thorough quality control inspections, ensuring that all zinc plate coatings met specified thickness and adherence standards.

Awards

- Zinc Plate Cutter of the Month, awarded for outstanding performance in quality control and efficiency.

- Recognized for exceeding production targets while ensuring adherence to safety protocols.

- Zinc Plate Cutter of the Year, awarded for consistent excellence in craftsmanship and work ethic.

- Recognized for exceptional attention to detail and ability to identify and correct potential production flaws.

Certificates

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Zinc Plate Cutter

Highlight your technical skills and experience.

Zinc plate cutters need to have a strong understanding of zinc plating, plate cutting, and sheet metal fabrication. Be sure to list your experience in these areas, as well as any relevant certifications or training you have received.Showcase your problem-solving skills.

Zinc plate cutters often need to troubleshoot and resolve equipment issues. Be sure to highlight your ability to identify and solve problems quickly and efficiently.Emphasize your quality control experience.

Zinc plate cutters are responsible for ensuring that all zinc coatings meet specified thickness and adherence standards. Be sure to highlight your experience in conducting quality control inspections and your commitment to maintaining high quality standards.Demonstrate your teamwork skills.

Zinc plate cutters often work as part of a team. Be sure to highlight your ability to work well with others and your willingness to contribute to the team’s success.

Essential Experience Highlights for a Strong Zinc Plate Cutter Resume

- Operate zinc plating equipment to apply protective coatings to metal components.

- Cut zinc plates to specified dimensions using a variety of tools and equipment.

- Conduct quality control inspections to ensure that zinc coatings meet specified thickness and adherence standards.

- Troubleshoot and resolve equipment issues to prevent production delays.

- Maintain a clean and organized work area to ensure safety and efficiency.

- Train and develop new team members to ensure a skilled and productive workforce.

- Collaborate with the engineering team to improve processes and resolve technical issues.

Frequently Asked Questions (FAQ’s) For Zinc Plate Cutter

What is the role of a Zinc Plate Cutter?

A Zinc Plate Cutter is responsible for cutting and shaping zinc plates to specified dimensions, as well as applying protective coatings to metal components using zinc plating equipment. They also conduct quality control inspections to ensure that all zinc coatings meet specified thickness and adherence standards, and troubleshoot and resolve equipment issues to prevent production delays.

What are the key skills required to be a successful Zinc Plate Cutter?

Key skills for a successful Zinc Plate Cutter include proficiency in zinc plating, plate cutting, and sheet metal fabrication, as well as a strong understanding of quality control standards and procedures. They should also have excellent problem-solving skills, be able to work independently and as part of a team, and be committed to maintaining a clean and organized work area.

What is the typical work environment for a Zinc Plate Cutter?

Zinc Plate Cutters typically work in manufacturing facilities, where they are exposed to noise, dust, and fumes. They may also work outdoors in all weather conditions. They must be able to stand for long periods of time and lift heavy objects.

What are the career prospects for a Zinc Plate Cutter?

Zinc Plate Cutters can advance to positions such as Lead Zinc Plate Cutter, Supervisor, or Quality Control Manager. With additional training and experience, they may also move into related fields such as welding, machining, or fabrication.

What are the earning prospects for a Zinc Plate Cutter?

The earning prospects for a Zinc Plate Cutter vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Metal and Plastic Machine Workers, which includes Zinc Plate Cutters, was $43,600 in May 2021.

What is the job outlook for a Zinc Plate Cutter?

The job outlook for Zinc Plate Cutters is expected to be good over the next few years. The demand for zinc-plated products is expected to grow as the construction and manufacturing industries continue to expand.

What are some tips for writing a standout Zinc Plate Cutter resume?

To write a standout Zinc Plate Cutter resume, be sure to highlight your technical skills and experience, showcase your problem-solving skills, emphasize your quality control experience, and demonstrate your teamwork skills. You should also tailor your resume to each job you apply for, and proofread your resume carefully before submitting it.

What are some common interview questions for a Zinc Plate Cutter?

Common interview questions for a Zinc Plate Cutter include: – What is your experience with zinc plating? – What are your skills in plate cutting and sheet metal fabrication? – How do you maintain quality control standards? – How do you troubleshoot and resolve equipment issues? – What is your experience working as part of a team?