Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sheet Metal Worker Apprentice interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sheet Metal Worker Apprentice so you can tailor your answers to impress potential employers.

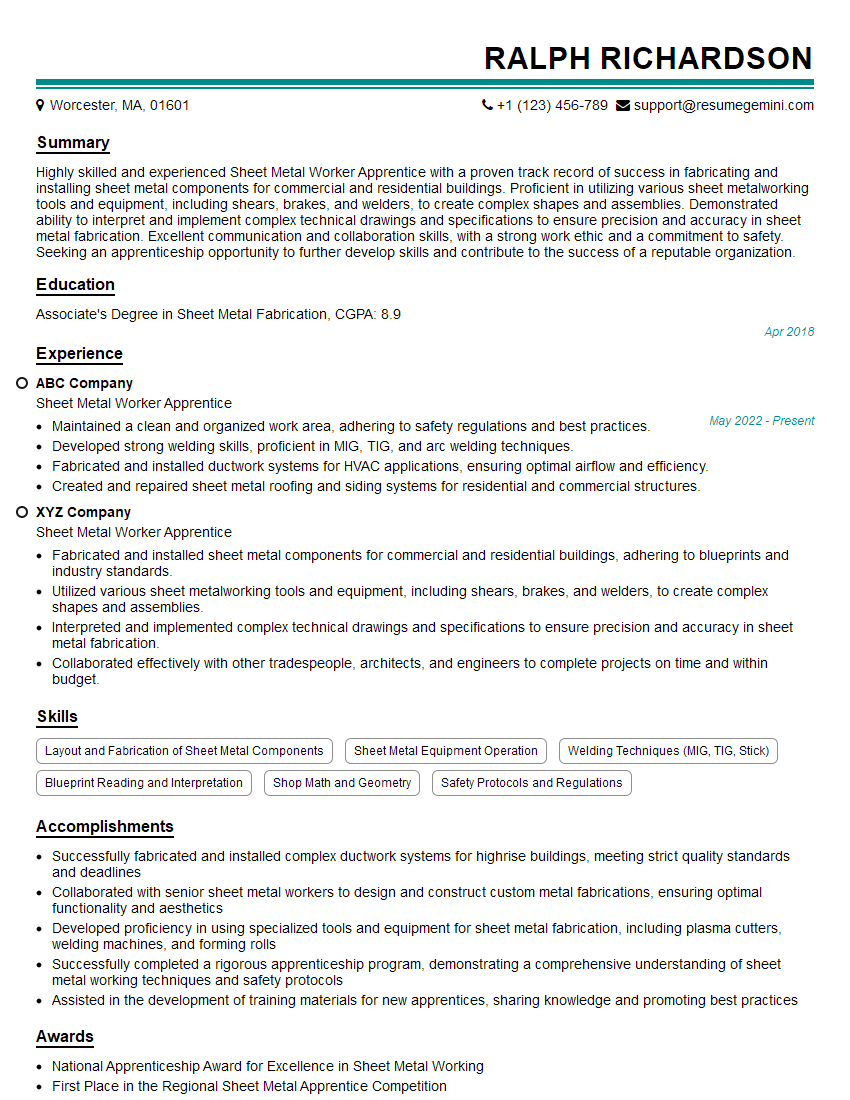

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Worker Apprentice

1. What are the common materials used in sheet metal fabrication and their properties?

Sheet metal fabrication involves working with different materials, each with unique properties:

- Steel: Strong, durable, and resistant to corrosion; commonly used in structural and automotive applications.

- Aluminum: Lightweight, corrosion-resistant, and strong; often used in aerospace, marine, and transportation industries.

- Stainless steel: Highly resistant to corrosion, heat, and wear; employed in food processing, chemical, and architectural applications.

- Copper: Excellent electrical and thermal conductivity; utilized in electrical wiring, roofing, and plumbing.

- Galvanized steel: Steel coated with zinc for corrosion protection; commonly used in roofing, gutters, and ductwork.

2. Explain the different types of sheet metal joints and their applications.

- Butt joint: Simplest joint, where two edges are joined together directly; used in light-duty applications.

- Lap joint: One sheet overlaps the other; provides strength and rigidity; commonly used in roofing and siding.

- Edge joint: Two edges are folded and interlocked; offers a strong and concealed joint; ideal for decorative or architectural applications.

- Hem joint: A sheet is folded over and folded back on itself; creates a strong, smooth edge; used in enclosures and containers.

- Groove joint: A groove is cut into one sheet, and a flange from the other sheet fits into the groove; provides a leak-proof and secure joint.

3. Describe the process of sheet metal layout and what factors are considered.

Sheet metal layout involves transferring the design onto the sheet metal for fabrication:

- Measurement and marking: Precise measurements and markings are made using rulers, squares, and other instruments.

- Pattern development: The shape of the design is transferred to the sheet metal using a variety of techniques, such as templating or computer-aided design.

- Material selection: The appropriate sheet metal material is selected based on the required properties and application.

- Material thickness: The thickness of the sheet metal is considered based on strength, weight, and cost requirements.

- Bend radii: The minimum bend radii for the sheet metal are determined to avoid cracking or distortions.

4. What are the different methods used for sheet metal fabrication, and when are they appropriate?

- Shearing: Cutting sheet metal using a guillotine or power shears; suitable for straight cuts.

- Press braking: Bending sheet metal using a press brake; allows for precise angles and bends.

- Rolling: Forming sheet metal into cylindrical or conical shapes using a rolling machine.

- Welding: Joining sheet metal pieces together using various welding techniques, such as MIG, TIG, or spot welding.

- Punching and riveting: Creating holes or joining sheet metal pieces using a punch press and rivets.

5. What tools and equipment are essential for a sheet metal worker apprentice?

- Measuring tools: Rulers, squares, protractors

- Layout tools: Scribers, marking pens, templates

- Cutting tools: Guillotine shears, power shears

- Bending tools: Press brake, bending pliers

- Welding equipment: Welding machine, welding torch

- Punches and rivets: Punch press, riveting gun

- Power tools: Drills, grinders

- Safety gear: Gloves, safety glasses, hearing protection

6. Explain the importance of safety in sheet metal fabrication and the precautions that should be taken.

- Wear appropriate safety gear: Gloves, safety glasses, and hearing protection.

- Operate machinery safely: Follow instructions, maintain equipment, and avoid loose clothing.

- Handle sharp materials carefully: Use proper tools and techniques when handling sheet metal.

- Be aware of potential hazards: Identify and assess risks before starting work.

- Maintain a clean and organized workspace: Clear away scrap metal, tools, and other materials.

7. What are some common problems encountered in sheet metal fabrication and how can they be resolved?

- Warpage: Caused by uneven heating or cooling; use clamping or jigs to minimize distortions.

- Cracking: Occurs due to excessive bending or forming; increase bend radii or use thicker material.

- Corrosion: Protect metal surfaces with coatings or galvanizing.

- Inaccurate bends: Ensure precise measurements and use properly calibrated bending equipment.

- Loose joints: Check tightness of welds or rivets, and use appropriate adhesives or sealants.

8. How important are communication and teamwork in sheet metal fabrication?

- Clear communication: Accurate instructions and understanding are crucial to avoid errors.

- Effective teamwork: Collaborating with colleagues ensures efficient execution of projects.

- Problem-solving: Shared knowledge and experiences help in finding solutions to fabrication challenges.

- Continuous improvement: Sharing ideas and best practices promotes learning and skill development within the team.

9. What are the industry standards and codes that are followed in sheet metal fabrication?

- ASHRAE: Standards for heating, ventilation, and air conditioning systems

- AWS: Standards for welding

- ASTM: Standards for materials testing

- NFPA: Standards for fire safety

- OSHA: Standards for workplace safety

10. How do you stay up-to-date with the latest techniques and advancements in sheet metal fabrication?

- Attend industry events and workshops

- Read trade publications and technical journals

- Take online courses or workshops

- Network with other sheet metal workers and professionals

- Seek opportunities for hands-on training and experimentation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Worker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Worker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Worker Apprentices assist experienced sheet metal workers in the fabrication, installation, and maintenance of sheet metal products, systems, and components. Their key responsibilities include:

1. Fabrication and Installation

Assist in cutting, bending, shaping, and assembling sheet metal components using hand tools, power tools, and machinery.

- Cut sheet metal using shears, plasma cutters, and laser cutters.

- Bend and shape sheet metal using brakes, rolls, and other forming equipment.

- Assemble sheet metal components using welding, riveting, bolting, and other fastening methods.

2. Maintenance and Repair

Assist in inspecting, testing, and repairing sheet metal products, systems, and components.

- Inspect sheet metal for damage, wear, and corrosion.

- Test sheet metal systems for leaks, airflow, and structural integrity.

- Repair sheet metal using patching, welding, and other methods.

3. Blueprint Reading and Interpretation

Read and interpret blueprints, drawings, and other technical documents.

- Identify materials, dimensions, and specifications from blueprints.

- Lay out and mark sheet metal for cutting and fabrication.

- Verify the accuracy of fabricated sheet metal components.

4. Safety and Quality Control

Follow safety protocols, including wearing appropriate safety gear and using tools and equipment safely.

- Adhere to safety guidelines and regulations.

- Identify and mitigate potential hazards.

- Inspect and ensure the quality of sheet metal products and installations.

Interview Tips

To ace your interview for a Sheet Metal Worker Apprentice position, follow these preparation tips and hacks:

1. Preparation

Review the job description thoroughly and identify the key skills and experience required.

- Research the company and the industry to demonstrate your knowledge and interest.

- Practice answering common interview questions, such as “Tell me about your experience with sheet metal fabrication.” and “Why are you interested in this role?”

- Prepare questions to ask the interviewer, showing your engagement and curiosity.

2. Dressing Professionally

Dress appropriately for the interview, opting for business casual or professional attire.

- First impressions matter, so present yourself neatly and professionally.

- Consider wearing comfortable shoes as you may be required to tour the facility.

3. Punctuality and Etiquette

Arrive on time for the interview and maintain a positive and respectful attitude throughout.

- Punctuality shows respect for the interviewer’s time.

- Be polite and courteous to everyone you meet, including receptionists and other staff.

- Thank the interviewer for their time and consideration, regardless of the outcome.

4. Enthusiasm and Passion

Demonstrate your enthusiasm for the sheet metal trade and explain why you are passionate about this field.

- Share your previous experience or training in sheet metal work.

- Highlight your willingness to learn and grow in the industry.

- Explain how your skills and interests align with the role of a Sheet Metal Worker Apprentice.

5. Be prepared to discuss safety

As safety is a critical aspect of sheet metal work, be prepared to answer questions about your understanding of safety protocols and your commitment to following them.

- Describe your experience with safety practices in previous jobs or training programs.

- Explain how you would approach a hazardous situation and prioritize safety.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sheet Metal Worker Apprentice, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sheet Metal Worker Apprentice positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.