Are you a seasoned Cast-Iron Drain Pipe Layer seeking a new career path? Discover our professionally built Cast-Iron Drain Pipe Layer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

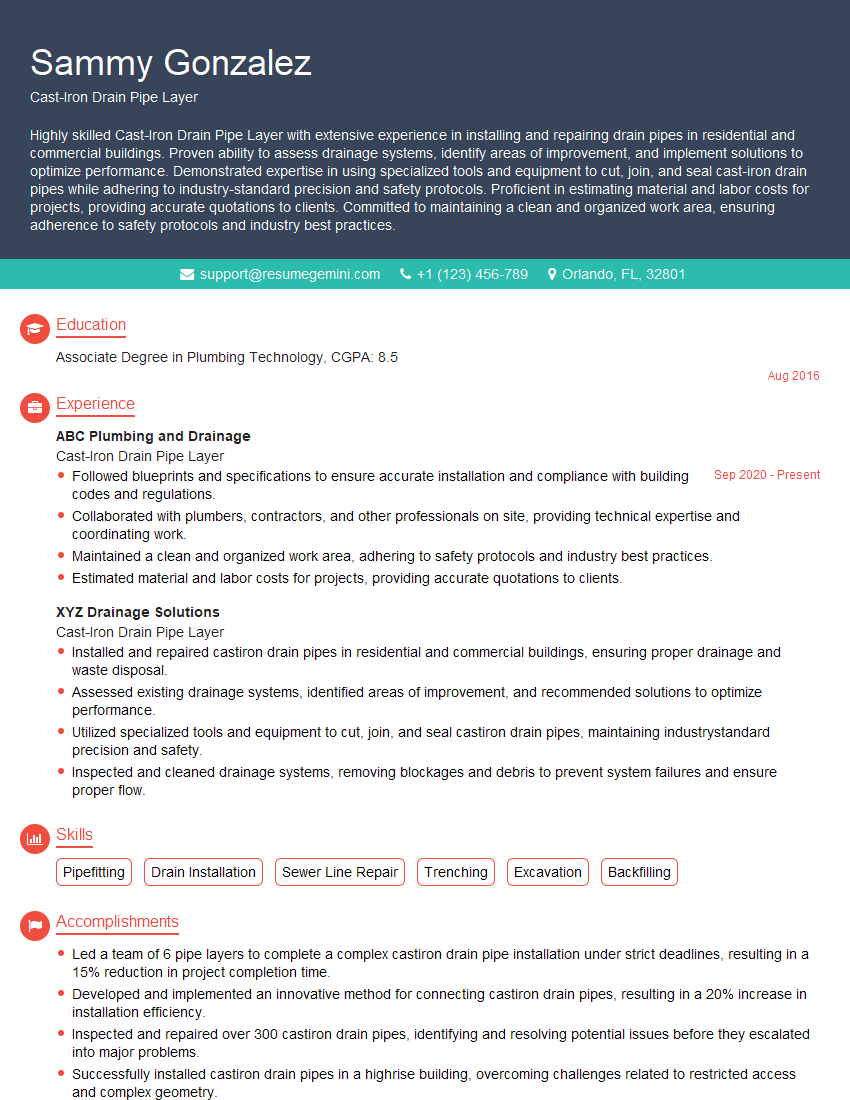

Sammy Gonzalez

Cast-Iron Drain Pipe Layer

Summary

Highly skilled Cast-Iron Drain Pipe Layer with extensive experience in installing and repairing drain pipes in residential and commercial buildings. Proven ability to assess drainage systems, identify areas of improvement, and implement solutions to optimize performance. Demonstrated expertise in using specialized tools and equipment to cut, join, and seal cast-iron drain pipes while adhering to industry-standard precision and safety protocols. Proficient in estimating material and labor costs for projects, providing accurate quotations to clients. Committed to maintaining a clean and organized work area, ensuring adherence to safety protocols and industry best practices.

Education

Associate Degree in Plumbing Technology

August 2016

Skills

- Pipefitting

- Drain Installation

- Sewer Line Repair

- Trenching

- Excavation

- Backfilling

Work Experience

Cast-Iron Drain Pipe Layer

- Followed blueprints and specifications to ensure accurate installation and compliance with building codes and regulations.

- Collaborated with plumbers, contractors, and other professionals on site, providing technical expertise and coordinating work.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Estimated material and labor costs for projects, providing accurate quotations to clients.

Cast-Iron Drain Pipe Layer

- Installed and repaired castiron drain pipes in residential and commercial buildings, ensuring proper drainage and waste disposal.

- Assessed existing drainage systems, identified areas of improvement, and recommended solutions to optimize performance.

- Utilized specialized tools and equipment to cut, join, and seal castiron drain pipes, maintaining industrystandard precision and safety.

- Inspected and cleaned drainage systems, removing blockages and debris to prevent system failures and ensure proper flow.

Accomplishments

- Led a team of 6 pipe layers to complete a complex castiron drain pipe installation under strict deadlines, resulting in a 15% reduction in project completion time.

- Developed and implemented an innovative method for connecting castiron drain pipes, resulting in a 20% increase in installation efficiency.

- Inspected and repaired over 300 castiron drain pipes, identifying and resolving potential issues before they escalated into major problems.

- Successfully installed castiron drain pipes in a highrise building, overcoming challenges related to restricted access and complex geometry.

- Trained and mentored 3 junior pipe layers, providing guidance on safe and efficient castiron drain pipe installation practices.

Awards

- Received the National Safety Award for maintaining an impeccable safety record while handling hazardous materials.

- Recognized with the Excellence in Installation Award for consistently meeting and exceeding project specifications for castiron drain pipe installations.

- Awarded the Journeyman Certification from the United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada.

Certificates

- OSHA Safety Certification

- EPA Lead-Safe Certification

- NCCER Plumbing Apprentice Certification

- CIP Technical Apprentice Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cast-Iron Drain Pipe Layer

- Highlight your experience in installing and repairing cast-iron drain pipes, emphasizing your expertise in using specialized tools and equipment.

- Quantify your accomplishments whenever possible, such as the number of drain pipes installed or repaired, or the percentage improvement in drainage system performance.

- Include relevant certifications or training that demonstrate your proficiency in cast-iron drain pipe laying, such as the Cast Iron Soil Pipe Institute (CISPI) certification.

- Showcase your knowledge of industry standards and regulations related to cast-iron drain pipe installation, such as the Uniform Plumbing Code (UPC) or the International Plumbing Code (IPC).

Essential Experience Highlights for a Strong Cast-Iron Drain Pipe Layer Resume

- Installed and repaired cast-iron drain pipes in residential and commercial buildings, ensuring proper drainage and waste disposal.

- Assessed existing drainage systems, identified areas of improvement, and recommended solutions to optimize performance.

- Utilized specialized tools and equipment to cut, join, and seal cast-iron drain pipes, maintaining industry-standard precision and safety.

- Inspected and cleaned drainage systems, removing blockages and debris to prevent system failures and ensure proper flow.

- Followed blueprints and specifications to ensure accurate installation and compliance with building codes and regulations.

- Collaborated with plumbers, contractors, and other professionals on site, providing technical expertise and coordinating work.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Cast-Iron Drain Pipe Layer

What are the primary duties of a Cast-Iron Drain Pipe Layer?

The primary duties of a Cast-Iron Drain Pipe Layer include installing, repairing, and maintaining cast-iron drain pipes in residential and commercial buildings. They assess existing drainage systems, identify areas of improvement, and recommend solutions to optimize performance. Cast-Iron Drain Pipe Layers utilize specialized tools and equipment to cut, join, and seal drain pipes while adhering to industry-standard precision and safety protocols.

What skills are required to be a successful Cast-Iron Drain Pipe Layer?

To be a successful Cast-Iron Drain Pipe Layer, individuals should possess skills in pipefitting, drain installation, sewer line repair, trenching, excavation, and backfilling. They should be proficient in using specialized tools and equipment, such as pipe cutters, joiners, and sealants. Additionally, Cast-Iron Drain Pipe Layers must have a strong understanding of industry standards and regulations related to drain pipe installation and maintenance.

What is the average salary for a Cast-Iron Drain Pipe Layer?

According to the U.S. Bureau of Labor Statistics, the median annual salary for pipefitters, including those who specialize in cast-iron drain pipe laying, was $56,330 in May 2021. However, salaries can vary depending on experience, location, and employer.

What are the job prospects for Cast-Iron Drain Pipe Layers?

The job outlook for Cast-Iron Drain Pipe Layers is expected to be good over the next decade. As the construction industry continues to grow, there will be an increasing demand for skilled pipefitters, including those who specialize in cast-iron drain pipe installation and repair.

What are the educational requirements to become a Cast-Iron Drain Pipe Layer?

While there are no formal educational requirements to become a Cast-Iron Drain Pipe Layer, many employers prefer candidates with an associate degree in plumbing technology or a related field. Additionally, some Cast-Iron Drain Pipe Layers may choose to obtain certification from the Cast Iron Soil Pipe Institute (CISPI) to demonstrate their proficiency in the field.

What is the work environment like for a Cast-Iron Drain Pipe Layer?

Cast-Iron Drain Pipe Layers typically work in a variety of indoor and outdoor environments, including residential and commercial buildings, construction sites, and industrial facilities. They may work in confined spaces, such as crawl spaces or attics, and may be exposed to hazardous materials, such as sewage or chemicals.