Are you a seasoned Maintenance Operator seeking a new career path? Discover our professionally built Maintenance Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

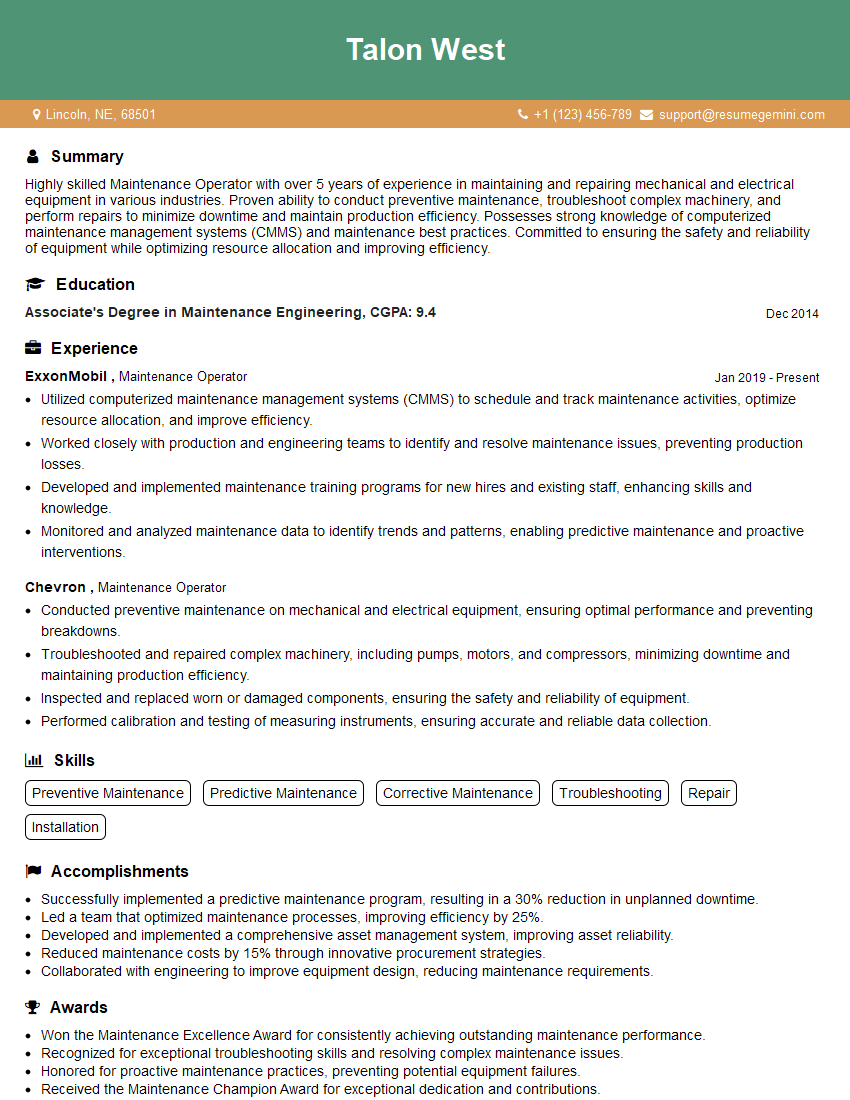

Talon West

Maintenance Operator

Summary

Highly skilled Maintenance Operator with over 5 years of experience in maintaining and repairing mechanical and electrical equipment in various industries. Proven ability to conduct preventive maintenance, troubleshoot complex machinery, and perform repairs to minimize downtime and maintain production efficiency. Possesses strong knowledge of computerized maintenance management systems (CMMS) and maintenance best practices. Committed to ensuring the safety and reliability of equipment while optimizing resource allocation and improving efficiency.

Education

Associate’s Degree in Maintenance Engineering

December 2014

Skills

- Preventive Maintenance

- Predictive Maintenance

- Corrective Maintenance

- Troubleshooting

- Repair

- Installation

Work Experience

Maintenance Operator

- Utilized computerized maintenance management systems (CMMS) to schedule and track maintenance activities, optimize resource allocation, and improve efficiency.

- Worked closely with production and engineering teams to identify and resolve maintenance issues, preventing production losses.

- Developed and implemented maintenance training programs for new hires and existing staff, enhancing skills and knowledge.

- Monitored and analyzed maintenance data to identify trends and patterns, enabling predictive maintenance and proactive interventions.

Maintenance Operator

- Conducted preventive maintenance on mechanical and electrical equipment, ensuring optimal performance and preventing breakdowns.

- Troubleshooted and repaired complex machinery, including pumps, motors, and compressors, minimizing downtime and maintaining production efficiency.

- Inspected and replaced worn or damaged components, ensuring the safety and reliability of equipment.

- Performed calibration and testing of measuring instruments, ensuring accurate and reliable data collection.

Accomplishments

- Successfully implemented a predictive maintenance program, resulting in a 30% reduction in unplanned downtime.

- Led a team that optimized maintenance processes, improving efficiency by 25%.

- Developed and implemented a comprehensive asset management system, improving asset reliability.

- Reduced maintenance costs by 15% through innovative procurement strategies.

- Collaborated with engineering to improve equipment design, reducing maintenance requirements.

Awards

- Won the Maintenance Excellence Award for consistently achieving outstanding maintenance performance.

- Recognized for exceptional troubleshooting skills and resolving complex maintenance issues.

- Honored for proactive maintenance practices, preventing potential equipment failures.

- Received the Maintenance Champion Award for exceptional dedication and contributions.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Plant Maintenance Manager (CPMM)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Maintenance Operator

- Highlight your experience in preventive and predictive maintenance, as these are crucial skills for maintaining equipment reliability and minimizing downtime.

- Quantify your accomplishments whenever possible. For example, instead of saying “troubleshooted and repaired complex machinery,” you could say “troubleshooted and repaired 15 complex machines, reducing downtime by 20%.”

- Showcase your knowledge of computerized maintenance management systems (CMMS). CMMS are widely used in the industry, and proficiency in using them is a valuable skill.

- Emphasize your ability to work independently and as part of a team. Maintenance operators often work alone, but they also need to be able to collaborate with others to resolve complex issues.

Essential Experience Highlights for a Strong Maintenance Operator Resume

- Conducted preventive and predictive maintenance on mechanical and electrical equipment to prevent breakdowns and ensure optimal performance.

- Troubleshooted and repaired complex machinery, including pumps, motors, and compressors, minimizing downtime and maintaining production efficiency.

- Inspected and replaced worn or damaged components to ensure the safety and reliability of equipment.

- Performed calibration and testing of measuring instruments to ensure accurate and reliable data collection.

- Utilized computerized maintenance management systems (CMMS) to schedule and track maintenance activities, optimize resource allocation, and improve efficiency.

- Worked closely with production and engineering teams to identify and resolve maintenance issues, preventing production losses.

- Developed and implemented maintenance training programs for new hires and existing staff, enhancing skills and knowledge.

Frequently Asked Questions (FAQ’s) For Maintenance Operator

What are the key skills required to be a successful Maintenance Operator?

The key skills required to be a successful Maintenance Operator include preventive maintenance, predictive maintenance, corrective maintenance, troubleshooting, repair, and installation.

What are the different types of maintenance that Maintenance Operators perform?

Maintenance Operators perform various types of maintenance, including preventive maintenance, predictive maintenance, and corrective maintenance. Preventive maintenance involves regular inspections and servicing of equipment to prevent breakdowns. Predictive maintenance uses data analysis to predict when equipment is likely to fail, allowing for proactive repairs. Corrective maintenance involves repairing equipment after it has broken down.

What are the different industries that Maintenance Operators work in?

Maintenance Operators work in various industries, including manufacturing, energy, transportation, and healthcare. They are responsible for maintaining and repairing equipment in these industries to ensure smooth operations.

What are the career advancement opportunities for Maintenance Operators?

Maintenance Operators can advance their careers by becoming Maintenance Supervisors, Maintenance Managers, or Plant Managers. They can also specialize in a particular area of maintenance, such as electrical maintenance or mechanical maintenance.

What is the average salary for a Maintenance Operator?

The average salary for a Maintenance Operator in the United States is around $50,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the job market trends for Maintenance Operators?

The job market for Maintenance Operators is expected to grow in the coming years. This is due to the increasing demand for skilled workers to maintain and repair equipment in various industries.