Are you a seasoned Pipe Setter seeking a new career path? Discover our professionally built Pipe Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

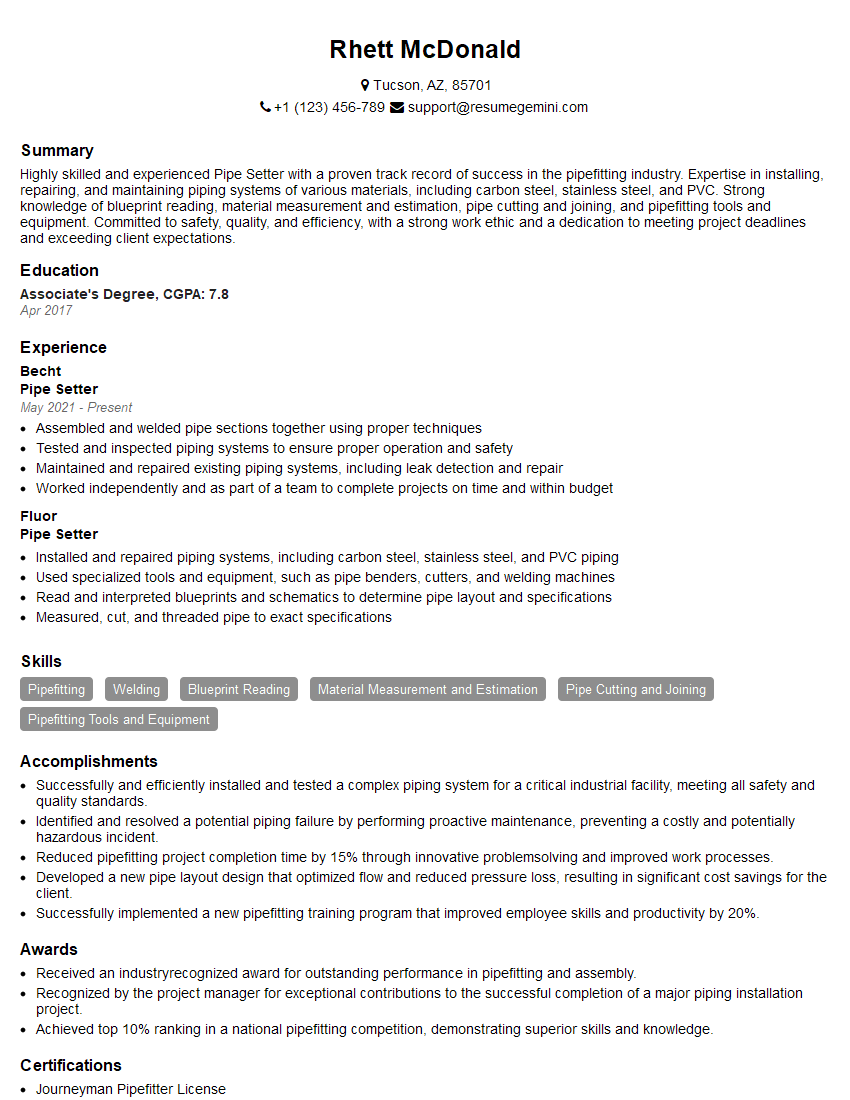

Rhett McDonald

Pipe Setter

Summary

Highly skilled and experienced Pipe Setter with a proven track record of success in the pipefitting industry. Expertise in installing, repairing, and maintaining piping systems of various materials, including carbon steel, stainless steel, and PVC. Strong knowledge of blueprint reading, material measurement and estimation, pipe cutting and joining, and pipefitting tools and equipment. Committed to safety, quality, and efficiency, with a strong work ethic and a dedication to meeting project deadlines and exceeding client expectations.

Education

Associate’s Degree

April 2017

Skills

- Pipefitting

- Welding

- Blueprint Reading

- Material Measurement and Estimation

- Pipe Cutting and Joining

- Pipefitting Tools and Equipment

Work Experience

Pipe Setter

- Assembled and welded pipe sections together using proper techniques

- Tested and inspected piping systems to ensure proper operation and safety

- Maintained and repaired existing piping systems, including leak detection and repair

- Worked independently and as part of a team to complete projects on time and within budget

Pipe Setter

- Installed and repaired piping systems, including carbon steel, stainless steel, and PVC piping

- Used specialized tools and equipment, such as pipe benders, cutters, and welding machines

- Read and interpreted blueprints and schematics to determine pipe layout and specifications

- Measured, cut, and threaded pipe to exact specifications

Accomplishments

- Successfully and efficiently installed and tested a complex piping system for a critical industrial facility, meeting all safety and quality standards.

- Identified and resolved a potential piping failure by performing proactive maintenance, preventing a costly and potentially hazardous incident.

- Reduced pipefitting project completion time by 15% through innovative problemsolving and improved work processes.

- Developed a new pipe layout design that optimized flow and reduced pressure loss, resulting in significant cost savings for the client.

- Successfully implemented a new pipefitting training program that improved employee skills and productivity by 20%.

Awards

- Received an industryrecognized award for outstanding performance in pipefitting and assembly.

- Recognized by the project manager for exceptional contributions to the successful completion of a major piping installation project.

- Achieved top 10% ranking in a national pipefitting competition, demonstrating superior skills and knowledge.

Certificates

- Journeyman Pipefitter License

- Certified Pipe Welder (CPW)

- National Institute for Certification in Engineering Technologies (NICET) Certification

- OSHA 30-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Setter

- Highlight your experience and skills in pipefitting, welding, and blueprint reading.

- Showcase your knowledge of different types of piping materials and their applications.

- Emphasize your ability to work independently and as part of a team.

- Provide specific examples of projects where you have successfully installed or repaired piping systems.

Essential Experience Highlights for a Strong Pipe Setter Resume

- Installed and repaired piping systems for various applications, including industrial, commercial, and residential

- Utilized specialized tools and equipment, such as pipe benders, cutters, and welding machines, to fabricate and assemble piping systems

- Read and interpreted blueprints and schematics to determine pipe layout and specifications

- Measured, cut, and threaded pipe to exact specifications

- Assembled and welded pipe sections together using proper techniques to ensure system integrity

- Tested and inspected piping systems to ensure proper operation and safety

- Maintained and repaired existing piping systems, including leak detection and repair

Frequently Asked Questions (FAQ’s) For Pipe Setter

What are the primary responsibilities of a Pipe Setter?

Pipe Setters are responsible for installing, repairing, and maintaining piping systems used in various industries. Their duties include reading and interpreting blueprints, measuring and cutting pipes, assembling and welding pipe sections, and testing and inspecting piping systems to ensure proper operation and safety.

What are the essential skills required for Pipe Setters?

Pipe Setters should possess strong skills in pipefitting, welding, blueprint reading, material measurement and estimation, and pipe cutting and joining. They should also be proficient in using various pipefitting tools and equipment.

What is the career outlook for Pipe Setters?

The job outlook for Pipe Setters is expected to grow in the coming years due to the increasing demand for skilled tradespeople in the construction industry. Pipe Setters with experience in specialized areas, such as welding or fabrication, may have better job prospects.

What industries employ Pipe Setters?

Pipe Setters are employed in various industries, including construction, manufacturing, shipbuilding, and oil and gas. They work on projects ranging from residential and commercial buildings to industrial plants and power generation facilities.

What are the educational requirements to become a Pipe Setter?

While formal education is not always required, many Pipe Setters have an associate’s degree or vocational training in a related field, such as pipefitting or welding. Apprenticeship programs are also available to provide hands-on training and experience.

What are the safety precautions that Pipe Setters must follow?

Pipe Setters must adhere to strict safety protocols, including wearing appropriate protective gear, using tools and equipment correctly, and following established procedures for handling hazardous materials and working at heights.

What is the work environment of a Pipe Setter?

Pipe Setters typically work in industrial settings, such as construction sites or manufacturing plants. They may work in various weather conditions and may be required to work in confined spaces or at heights.

What is the career path for Pipe Setters?

Experienced Pipe Setters may advance to supervisory roles, such as Foreman or Superintendent. They may also specialize in a particular area of pipefitting, such as welding or fabrication. Some Pipe Setters may also start their own businesses.