Are you a seasoned Sheet Ironworker seeking a new career path? Discover our professionally built Sheet Ironworker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

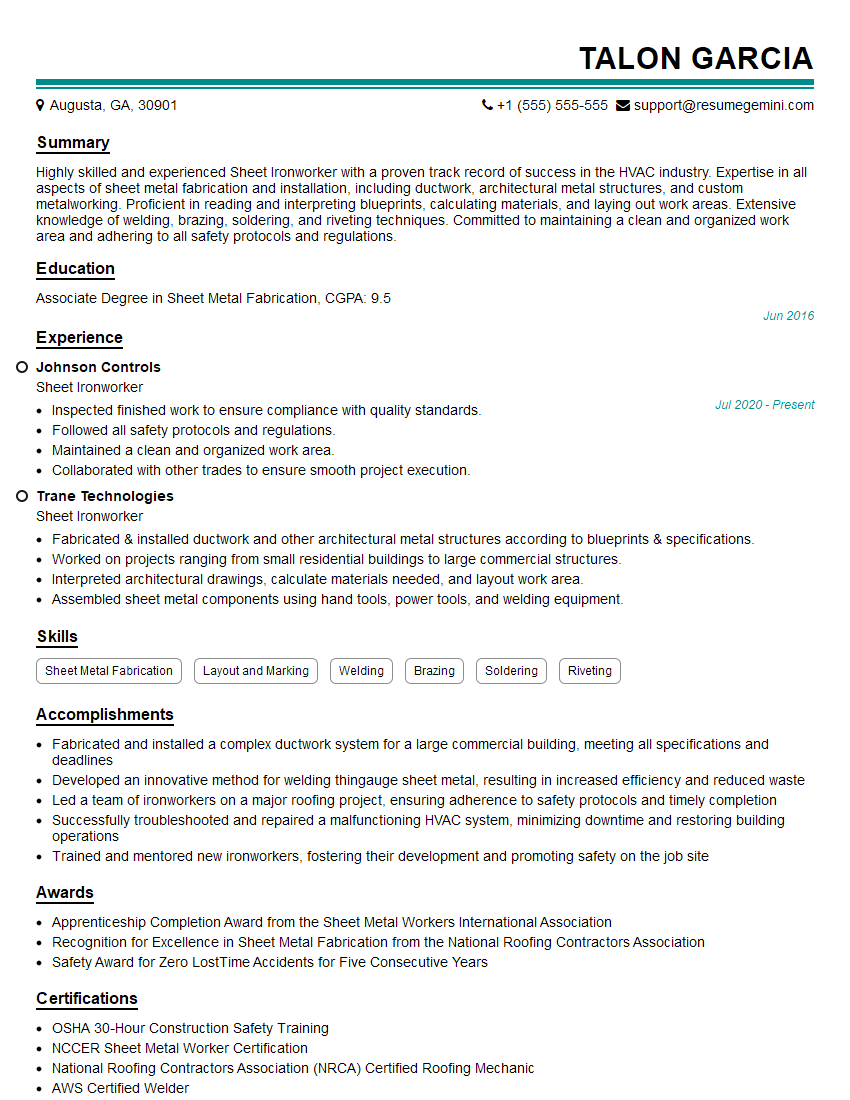

Talon Garcia

Sheet Ironworker

Summary

Highly skilled and experienced Sheet Ironworker with a proven track record of success in the HVAC industry. Expertise in all aspects of sheet metal fabrication and installation, including ductwork, architectural metal structures, and custom metalworking. Proficient in reading and interpreting blueprints, calculating materials, and laying out work areas. Extensive knowledge of welding, brazing, soldering, and riveting techniques. Committed to maintaining a clean and organized work area and adhering to all safety protocols and regulations.

Education

Associate Degree in Sheet Metal Fabrication

June 2016

Skills

- Sheet Metal Fabrication

- Layout and Marking

- Welding

- Brazing

- Soldering

- Riveting

Work Experience

Sheet Ironworker

- Inspected finished work to ensure compliance with quality standards.

- Followed all safety protocols and regulations.

- Maintained a clean and organized work area.

- Collaborated with other trades to ensure smooth project execution.

Sheet Ironworker

- Fabricated & installed ductwork and other architectural metal structures according to blueprints & specifications.

- Worked on projects ranging from small residential buildings to large commercial structures.

- Interpreted architectural drawings, calculate materials needed, and layout work area.

- Assembled sheet metal components using hand tools, power tools, and welding equipment.

Accomplishments

- Fabricated and installed a complex ductwork system for a large commercial building, meeting all specifications and deadlines

- Developed an innovative method for welding thingauge sheet metal, resulting in increased efficiency and reduced waste

- Led a team of ironworkers on a major roofing project, ensuring adherence to safety protocols and timely completion

- Successfully troubleshooted and repaired a malfunctioning HVAC system, minimizing downtime and restoring building operations

- Trained and mentored new ironworkers, fostering their development and promoting safety on the job site

Awards

- Apprenticeship Completion Award from the Sheet Metal Workers International Association

- Recognition for Excellence in Sheet Metal Fabrication from the National Roofing Contractors Association

- Safety Award for Zero LostTime Accidents for Five Consecutive Years

Certificates

- OSHA 30-Hour Construction Safety Training

- NCCER Sheet Metal Worker Certification

- National Roofing Contractors Association (NRCA) Certified Roofing Mechanic

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Ironworker

- Highlight your welding skills and experience.

- Showcase your knowledge of sheet metal fabrication techniques.

- Emphasize your ability to read and interpret blueprints.

- Provide examples of your work on complex projects.

- Showcase your commitment to safety and quality workmanship.

Essential Experience Highlights for a Strong Sheet Ironworker Resume

- Fabricate and install ductwork and other architectural metal structures according to blueprints and specifications.

- Interpret architectural drawings, calculate materials needed, and layout work area.

- Assemble sheet metal components using hand tools, power tools, and welding equipment.

- Inspect finished work to ensure compliance with quality standards.

- Measure, lay out, and cut sheet metal using hand tools and power tools.

- Repair and maintain existing sheet metal structures.

- Collaborate with other trades to ensure smooth project execution.

Frequently Asked Questions (FAQ’s) For Sheet Ironworker

What is a Sheet Ironworker?

A Sheet Ironworker is a skilled tradesperson who works with sheet metal to create and install various structures and components, such as ductwork, roofing, and architectural features.

What is the job outlook for Sheet Ironworkers?

The job outlook for Sheet Ironworkers is expected to be good in the coming years, with a projected growth rate of 12% from 2021 to 2031.

Can I become a Sheet Ironworker through an apprenticeship?

Yes, many Sheet Ironworkers enter the field through apprenticeships that provide on-the-job training and classroom instruction.

What skills are required to be a successful Sheet Ironworker?

Successful Sheet Ironworkers typically have strong welding skills, knowledge of sheet metal fabrication techniques, and the ability to read and interpret blueprints.

What are the safety precautions that Sheet Ironworkers must follow?

Sheet Ironworkers must follow various safety precautions, including wearing protective gear, using proper tools and equipment, and adhering to established safety protocols.

What are the different types of projects Sheet Ironworkers work on?

Sheet Ironworkers work on a variety of projects, including the installation of ductwork for HVAC systems, the fabrication of architectural metal features, and the repair of existing sheet metal structures.

What is the average salary of a Sheet Ironworker?

The average salary for Sheet Ironworkers varies depending on experience, location, and the specific industry in which they work.